Filter press is the commonly used equipment for tailing coal treatment and dewatering in coal washing plant at this stage, which has the advantages of strong processing capacity, good dewatering effect, low noise, low energy consumption and so on. The fine coal slurry (particle size below 0.25mm) dewatering of Huibaodi Coal Wash Plant uses ZKG450/2000-U type fast-opening diaphragm filter press, and the products are transported out by belt conveyor. The fast-opening diaphragm filter press has a certain degree of clogging problem in the process of using, which affects the filtering effect of fine coal sludge. For this reason, the fast-opening diaphragm filter press system is optimised to improve the fine coal slurry treatment effect to a certain extent. 1 Overview of the coal washing plant and the use of the filter press The Hupoji Coal Washing Plant is a pit-type coal washing plant constructed for the Hupoji Mine, with a design capacity of 1.5 million t/a, and the raw coal to be washed comes from the Hupoji Mine. The plant adopts the combined process of desliming and non-pressure feeding three-product heavy media + TPS separator + flotation. The dewatering of flotation coal is completed by two ZKG450/2000-U type fast-opening diaphragm filter presses. Due to the difficulties of many working steps, complicated procedures and control points of the fast-opening diaphragm filter presses, the equipment has been operating with high failure rate since it was put into operation, and the dewatering capacity of the flotation concentrate is low, resulting in high water content of the concentrate, so it is necessary to upgrade and optimise the original equipment. The structure of the filter press system of ZKG450/2000-U quick-opening diaphragm filter press used in Hupoji Coal Wash Plant consists of the main machine, auxiliary machines, valves, pipelines and so on.The filter is installed in a closed pressurised silo and the fallout from the filter press is transported using a scraper conveyor, with a discharge device at the head of the machine. The turbid liquid formed during the filtering process is pumped into the filter tank by means of a feed pump. Under pressure in the pressurised silo, the liquid from the filtration process flows out, while the solid particles form a cake that rotates with the filter discs and is then transported to the discharge unit via a scraper conveyor at the dispensing valve position. When a certain amount of material accumulates in the discharge unit, it will be discharged out of the filter intermittently, and the whole pressurised filtration process can be completed fully automatically.

2 Working Principle of Filter Press When filtration starts, the coal slurry water enters into each filter chamber through the feeding ports in the middle of the thrust plates on both sides under the push of the feeding pump, and the coal slurry water is separated from the solid-liquid by the pressure of the feeding pump. Due to the action of filtering medium, the solids larger than the gap of the filter cloth remain in the filter chamber to form filter cake; the filtrate and a small part of very fine coal sludge smaller than the gap of the filter cloth are discharged by the discharge valve and recycled. In use, if it is necessary to filter the cake with lower moisture, high pressure compressed air can be fed into the air inlet at the upper right corner of the upper push plate to press the cake to further reduce its moisture; or high pressure air can be fed into the air inlet at the centre of the press plate to pass through the cake layer and carry out the intermediate air flow to further squeeze out the excess water in the cake.

3 Analysis of problems in field application In the field application of quick-opening diaphragm filter press, it is found that when the equipment is shut down in emergency or the belt conveyor for transporting fine coal is shut down, it is necessary to discharge the quick-opening diaphragm filter press in time. However, due to the problem of high liquid level in the feeding cylinder of the fast-opening diaphragm filter press, it is difficult to discharge the filter, which is very easy to cause the main shaft of the filter to block. If the material is forced to be discharged, there will be overflow of the barrel. When the quick-opening diaphragm filter press cannot be used normally, the coal sludge in the thickening pool cannot be discharged in time, which affects the normal production of the coal washing plant.

4 System Optimisation Study Filter in normal use found that the level of the upper material cylinder is often in the 50% above, if the normal discharge is not very easy to program you to block the rotationProblems. Therefore, the optimisation of the filter system is considered in the paper in terms of the discharge process of the filter and the spindle speed.

4.1 Optimisation of spindle speed In general, the spindle speed of the filter is reasonably set in the range of 0.87~1.5r/min, and the rotational speed of the filter is set at 1.01r/min when dewatering fine coal slurry in the field. The lower the rotational speed of main shaft, the lower the number of slurry boards, the lower the product moisture and the more likely to be blocked; the higher the rotational speed, the higher the product moisture, and the product moisture will not meet the requirements after the rotational speed exceeds a certain value. Through the above analyses and combining with the previous research results, it is decided to increase the main shaft speed of the filter from 1.01r/min to 1.30r/min, so as to ensure that the filter can operate efficiently.

4.2 Optimisation of discharging process When the liquid level in the upper material cylinder is lower than 20%, the bottom flow pump will automatically feed, when the liquid level is higher than 80%, the bottom flow pump will stop working. If there is an urgent need to stop coal slurry or coal in the process of pressurisation and filtration, the bottom flow pump will still work automatically according to the liquid level of the upper barrel, generally the liquid level in the upper barrel is 60~80%, at this time, the material of the slurry tank will flow into the upper barrel, and when the inflow exceeds 40% of the liquid level, the upper barrel will be overflowing. If the material in the slurry tank can not be emptied quickly, the filter is very prone to blocking in the subsequent operation, if the material in the slurry tank can be emptied, there will be no blocking. The problem of emptying the slurry tank can be solved by reforming the slurry tank discharge method of the quick-opening diaphragm filter press. At this stage, the following two methods can be used to discharge the slurry tank of the quick-opening diaphragm filter press: Lower the liquid level in the upper barrel to ensure that the upper barrel has enough space to store materials. However, if the liquid level in the slurry loading cylinder is lowered too much, there is the problem of frequent startup of the bottom flow pump, which is not conducive to the efficient development of coal washing; if the liquid level is lowered too little, the storage space cannot be increased effectively, and the material in the loading cylinder will still have overflow problems. By improving the discharge system, the slurry tank materials can be discharged to other locations for temporary storage. The specific improvement is to optimise the discharge piping arrangement, so that the material in the slurry tank can be discharged to the protection box, and then returned to the thickening tank; the material in the thickening tank can be pumped to the upper barrel by using a bottom-flow pump, so as to achieve the cycle of material loading. After the above improvement, the discharge of materials in the slurry tank will not affect the liquid level in the upper barrel, thus effectively solving the problem of overflowing barrel in the upper barrel.

5 Analysis of the effect of modification Optimisation of the main shaft speed and discharge process of the fast-opening diaphragm filter press at the Hupoji Coal Washing Plant. After optimisation, the moisture content of the product produced by the filter is within a reasonable range, and at the same time, the path of material discharge in the slurry tank is shifted from the original loading cylinder to the thickening pool, thus effectively avoiding the overflow problem of the loading cylinder. The material discharge pipework was flanged during the on-site modification and optimisation, so that it can be dismantled and replaced in the event of serious wear and clogging. After the field application, the working condition of the quick-opening diaphragm filter press after the completion of the modification was investigated. It was found that when there is an emergency stoppage of coal slurry or coal in the coal washing plant, the materials in the slurry tank can be discharged into the protection box to achieve timely emptying of materials, and the problem of filter spindle plugging was increased from an average of once every three months before the renovation to once every nine months, and the incidence of filter spindle plugging has been reduced through the optimisation effectively. Through optimisation, the annual investment can be reduced by about 103,000 RMB, which not only reduces the labour intensity of operators but also shortens the time of equipment maintenance, and to a certain extent improves the economic benefits of the coal washing plant. At the same time, the upgrading reduces the product moisture, reduces the use of tap water, and saves a lot of social costs. The labour intensity of the operators has been reduced from four persons to only two persons. The pollution of the surrounding environment by coal slurry and the noise pollution of the flotation workshop have been greatly reduced, bringing significant social benefits.

6 Conclusion In this paper, the model ZKG450/2000-U fast-opening diaphragm filter press system used for fine coal slurry in the coal washing plant at the bottom of the slopes is optimised, specifically, the main shaft speed is optimised from 1.01r/min to 1.30r/min, and the product not only meets the requirement of water content but also improves the operating efficiency of the filter; the discharge process of the slurry tank is optimised, specifically the material in the slurry tank can be discharged into the protection box and then returned to the thickening pool, thus avoiding the material in the slurry tank from flowing into the feeding cylinder and leading to material overflow problems. The slurry tank discharge process is optimised, specifically, the material in the slurry tank can be discharged to the protection box, and then returned to the thickening pool, thus avoiding the material in the slurry tank to flow into the feeding cylinder, resulting in material spillage, and reducing the incidence of filter spindle jamming. After the application on site, the interval of filter blockage rate has increased from 3 months to 9 months, and it is estimated that the annual cost can be saved about 103,000 yuan, which effectively reduces the number of filter shaft blockage times and improves the comprehensive operating rate of coal washing equipment. After the fast-opening diaphragm filter press was formally put into use in Hu Po Di Coal Wash Plant, it saved a lot of operating costs for the plant due to its advantages of fast filtration and unloading speed, low moisture of the filter cake, large processing capacity, and high degree of automation; meanwhile, the machine has strong adaptability to the granularity composition of the incoming material, and it has a broad development prospect in processing viscous materials with fine granularity and high concentration.

Author:Zhao Zhenzhen

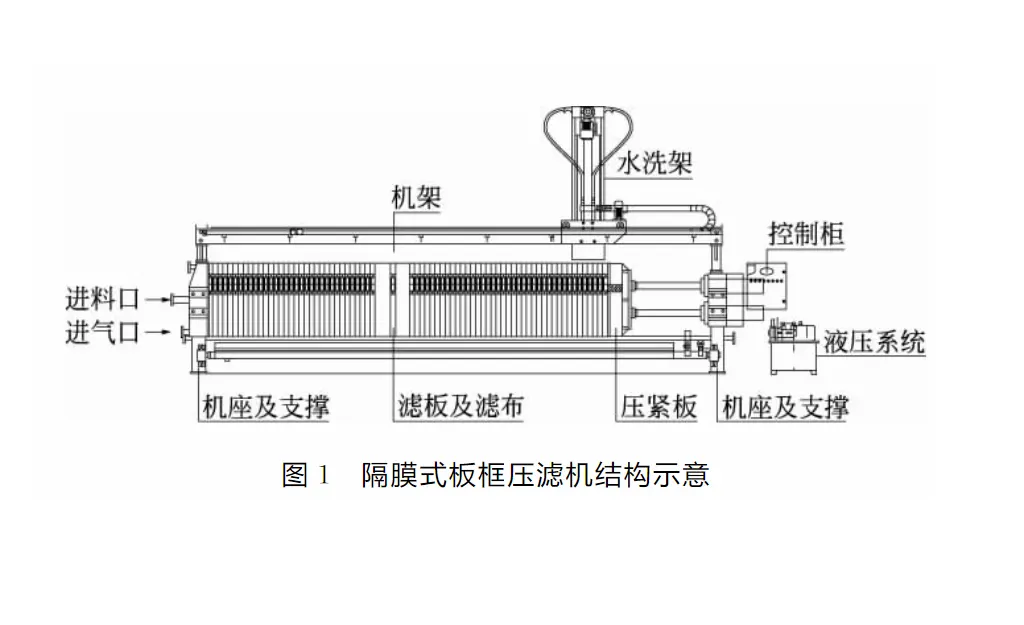

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses