introductory

機械化、智能化發展使得煤炭開采愈加高效。在高強度開采下,原煤中的細顆粒占比顯著升高,給后續煤炭洗選帶來諸多問題,在細煤泥回收中尤為凸顯。煤炭生產企業高質量發展、環境規制趨于嚴格的背景下,合理處置細粒煤泥成為煤炭企業面臨著重要挑戰。經過多年的技術開發和應用實踐,已形成了較為成熟的煤泥分選技術體系,常用的煤泥回收工藝設備包括:壓濾機、加壓過濾機和沉降離心機。filter press入料適應性強、濾液澄清度高、運行成本低,但產品水分偏高、占地較大;加壓過濾機和沉降離心機產品水分低、單機處理能力大、占地較小、自動化程度高,但加壓過濾機系統復雜、投資及運行成本較高,沉降離心機回收下限偏高,轉子需要定期維修。三種設備各具特點,在國內外均得到了廣泛應用,除了單設備回收工藝外,還衍生出“加壓過濾+沉降離心”“加壓過濾+壓濾”“沉降離心+壓濾”等聯合工藝。只有結合煤泥性質、煤泥量和廠房空間等條件選擇合適的煤泥回收設備、工藝才能經濟、高效地回收煤泥。另外,工藝布置形式也是煤泥處置的一大難題,尤其對于空間受限的項目,合理利用現有空間布置工藝可為企業節省可觀的成本。布爾洞選煤廠是在現有的礦井工業場地新增布置,針對其細煤泥水分高、灰分高、燃點低等特性,以及現有工業場地狹小、無法新增用地的特點,探討了細煤泥回收工藝選擇與布置方法。

1原煤煤質特點及細煤泥特性布爾洞煤礦選煤廠為動力煤選煤廠,是布爾洞煤礦的配套選煤廠,主要入選該礦原煤。布爾洞煤礦位于神東礦區東勝煤田內,生產能力為240萬t/a,開采煤層有4層,分別為4-1、4-2上、4-2及6-2號煤層,其中4-1、4-2上和4-2號煤層為大部可采的較穩定煤層,6-2號煤層為全區可采的穩定煤層。此4層煤賦存深度較淺,煤層結構簡單,不含或僅含一層夾矸。頂板巖性主要是粉砂巖和砂質泥巖;底板巖性主要是砂質泥巖,局部為細砂巖。該煤礦各煤層有害成分含量低,灰分、硫分含量低,且發熱量較高,是良好的民用和動力用煤。布爾洞煤礦的煤質化驗資料顯示:原煤灰分為35.24%,內水平均為8%,外水約為14%。為了研究原煤的泥化特性和次生煤泥的含量,分別進行了100~13mm原煤的轉筒泥化試驗和次生煤泥的篩分試驗。隨著翻轉時間的延長,高粒級原煤產率逐漸降低,次生煤泥產率逐漸增高,-0.045mm粒級細泥比重較高且灰分逐漸升高,說明煤質較硬,且易碎,原煤泥化現象較嚴重。次生煤泥中各粒級灰分隨著粒級的減小而逐漸升高,-0.25mm煤泥含量達96.52%,-0.045mm細泥產率84.41%,灰分高達89.56%,嚴重影響煤泥水沉降,增加煤泥水處理難度。因此在設計中必須充分考慮原煤泥化嚴重、細泥多的特性,合理選擇細煤泥回收工藝和工藝布置。

2細煤泥回收處理工藝選擇目前應用較多的動力煤選煤廠細煤泥回收工藝主要有:壓濾機單獨回收工藝、加壓過濾機單獨回收工藝、“加壓過濾機+壓濾機”兩段回收工藝[2]、“篩網沉降離心機+壓濾機”兩段回收工藝。

1) Filter press separate recycling process. Filter press can realise clear water in one press, and it is the ideal gatekeeper for the closed circuit recycling of washing water in coal beneficiation plant. This process is suitable for all power coal processing plants, especially for coal slurry content is small, and the content of fine-grained slurry in the coal slurry is more, it is the ideal process for the fine slurry dewatering and recycling system of the coal processing plant with more serious mud phenomenon.

2) Pressurised filter separate recovery process. Pressurised filter has the advantages of good dewatering effect, large processing capacity, and loose and easy mixing of filtered products. This process is suitable for coal slurry content is larger, less fine sludge content of the coal processing plant, while requiring a higher degree of automation of the washing process, and the use of pressurised filters to do the industrial test is better, or in the same mine to deal with the same type of coal when the effect is more pronounced in the coal processing plant. Pressurised filter feed in general -0.045mm particle content is less than 40%, coal slurry recovery effect is better, for the serious mud, fine-grained material content is higher in the coal plant, because of its high content of fine-grained materials, will lead to pressurised filter capacity is greatly reduced, and even equipment can not operate normally.

3)“加壓過濾機+壓濾機”兩段回收工藝。該工藝采用一段加壓過濾機回收+0.045mm粒級的一段底流粗煤泥,二段隔膜壓濾機回收-0.045mm粒級的二段底流細煤泥,適用于煤泥一次沉淀較為困難,+0.045mm粒級粗煤泥含量較高,且加壓過濾機處理效果良好同時要求水分含量低的選煤廠。4)“篩網沉降離心機+壓濾機”單獨回收工藝。該工藝采用一段篩網沉降離心機回收+0.045mm粒級的一段底流粗煤泥,二段隔膜壓濾機回收-0.045mm粒級的二段底流細煤泥,適用于煤泥一次沉淀較為困難,+0.045mm粒級粗煤泥含量較高,-0.045mm細煤泥含量低于20%,原煤不泥化或泥化現象不嚴重的選煤廠。由于布爾洞煤礦選煤廠煤質泥化較為嚴重,煤泥中+0.045mm粒級含量不高,僅為15.59%;且-0.045mm含量很高,達到了84.41%,因此不宜采用加壓過濾機和篩網沉降離心機回收,不適合采用兩段回收。通過以上分析最終確定本廠細煤泥回收采用壓濾機單獨回收工藝。

3工藝布置選擇壓濾機回收系統的工藝布置主要與煤泥產品走向、總平面位置、濃縮車間位置及煤泥晾干場位置等因素有關。主要有以下幾種布置形式:

1)壓濾回收系統、煤泥晾干場集中一體布置。壓濾回收系統單獨呈壓濾車間布置,并與煤泥晾干場集中一體布置。壓濾車間兩層布置,二層布置入料攪拌桶和壓濾機,一層部分布置入料泵等設備,部分做煤泥落地場地;煤泥晾干場布置在一層。該工藝流程為壓濾機拉板卸料的煤泥直接落至一層地面緩沖堆放,通過鏟車鏟入煤泥晾干場內進行自然晾干后外運。該布置形式適用于工業場地位置受限,主廠房周圍場地不足,且沒有壓濾車間、煤泥晾干場分開布置場地;原煤煤質較差,壓濾脫水效果較差,煤泥水分、灰分均偏高,發熱量較低,不適宜直接摻入末煤產品中;煤泥含水量太高,不適合膠帶轉載;煤泥燃點低,不適用進行干燥降水[6];煤泥干燥成本太高,沒有經濟效益的選煤廠。

2) Filter press recovery system and coal slurry drying yard are arranged separately. The filter press recovery system is arranged separately in the filter press workshop, and the coal slurry drying yard is arranged separately. The filter press workshop is arranged in two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collecting scraper and transferring belt conveyor, etc. The coal slurry drying yard is arranged according to the closed coal slurry drying yard. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal sludge unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, feeds to the transferring belt conveyor, and then is transported to the coal sludge drying yard for unloading and stacking, and then is naturally dried or dried and transported out. This arrangement form is suitable for industrial site location restrictions, insufficient space around the main plant, filter press workshop, coal slurry drying field can not be centrally arranged; raw coal quality is poor, the effect of filter press dewatering is poor, slurry moisture, ash are high, low calorific value, it is not suitable for direct blending into the final coal products; coal slurry drying field needs to be arranged in the drying facilities of the coal preparation plant.

3) Filter press recovery system, main plant and coal slurry drying yard are centrally arranged as a whole. Filter press recovery system and coal sludge drying yard are arranged in one side of the main plant, with two layers, the second layer is arranged with feeding mixing drum and filter press, the first layer is partly arranged with feeding pump and other equipment, and partly as a coal sludge landing site; the coal sludge drying yard is arranged on one layer. The process is that the coal slurry discharged from the filter press pulling plate directly falls to the ground buffer pile on the ground floor, and is shovelled into the coal slurry drying field by shovel to dry naturally and then transported out. This arrangement form is suitable for the industrial site is flat and spacious, convenient for centralised arrangement; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are high, the heat content is low, it is not suitable for directly mixing into the final coal products; the one-piece arrangement meets the requirements of fire protection partition; the moisture content of coal slurry is too high, it is not suitable for the tape reproduction; the burning point of coal slurry is low, it is not suitable for drying and descaling; the cost of drying coal slurry is too high, it does not have economic benefits. Coal processing plant.

4) The filter press recovery system and the main plant are centrally arranged as a whole, and the coal slurry drying yard is arranged separately. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is arranged with feed pump, filtrate pump, coal slurry collection scraper and transfer belt conveyor. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal slurry unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, and then feeds to the transferring belt conveyor, and is transported to the coal slurry drying yard for unloading and stacking, and then is naturally dried or dried in the coal slurry drying yard for external transport. This arrangement form is one of the most commonly used arrangement forms for power coal processing plant. This arrangement form is suitable for the industrial site is flat and spacious, the space location is rich; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are on the high side, the calorific value is low, it is not suitable to be directly mixed into the final coal products; the coal slurry drying field needs to be arranged with drying facilities of the coal beneficiation plant.

5) Filter press recovery system is arranged separately, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged separately in the filter press workshop, which is arranged in two layers, the second layer is arranged with feed mixing drum and filter press, and the first layer is arranged with feed pumps, filtrate pumps, coal slurry collection scraper and transfer belt conveyor, etc. The process is that the coal slurry discharged from the pulling plate of the filter press falls directly to the collection scraper, and then feeds to the transfer belt conveyor. The process flow is that the coal slurry discharged from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the end of the coal product belt conveyor for blending into the silo. This arrangement form is suitable for industrial site location restrictions, the main plant is not enough space around the main plant, the filter press workshop can not be centrally arranged with the main plant; the raw coal quality is good, the filter press dewatering effect is good, the coal slurry has a high calorific value and is suitable for blending into the final coal products; the integrated arrangement with the main plant can not meet the requirements of the fire protection zoning, and only a separate arrangement can meet the requirements of the fire protection of the coal processing plant.

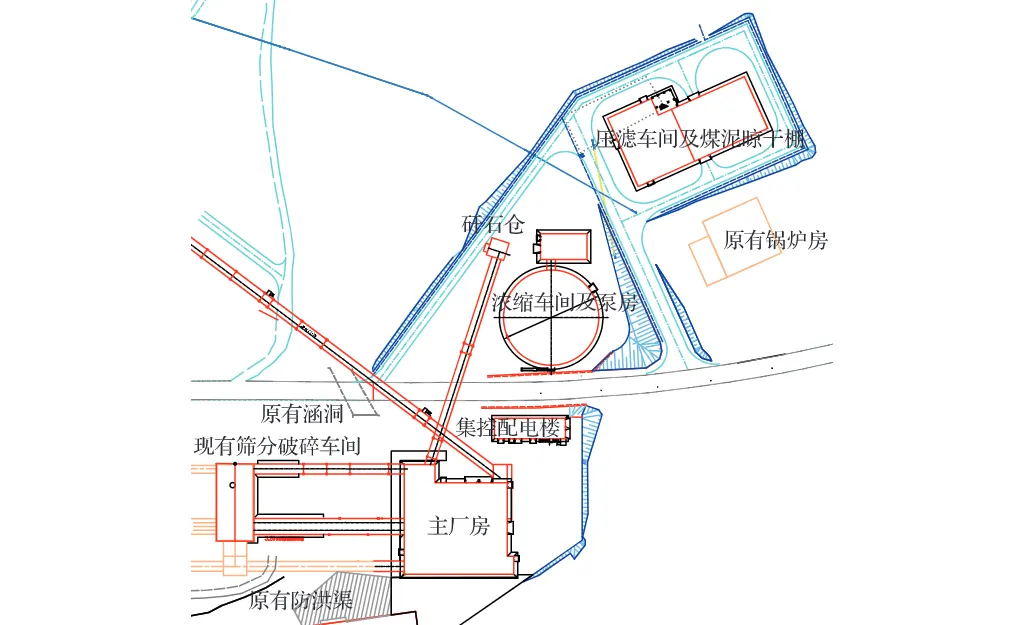

6) Filter press recovery system is centrally arranged with the main plant, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing drum and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collection scraper and reproduction belt conveyor, etc. The process is that the coal slurry unloaded from the pull plate of the filter press falls directly to the collection scraper and reproduction belt conveyor. The process flow is that the coal slurry unloaded from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the main plant for blending into the silo on the belt conveyor of the final coal products. This arrangement is also one of the most commonly used arrangement forms in power coal processing plants. This arrangement is suitable for the coal processing plant with flat and spacious industrial site, rich space location; good quality of raw coal, good dewatering effect of filter press, high heat content of coal slurry, which is suitable for blending into the final coal products; and the integrated arrangement with the main plant to meet the requirements of fire protection zoning. By comparing the six process arrangement forms of the filter press recovery system, combined with the general layout of the industrial site of the coal processing plant in Bourdong Coal Mine, as shown in Figure 1.

It can be seen that Bourdong coal processing plant is in the existing mine industrial site new arrangement, the existing industrial site is narrow, the remaining space is small and scattered, can not be newly purchased land, the main plant around the site is not enough, so there is no filter press workshop, coal slurry drying field separate layout site, coal slurry low ignition point is not suitable for drying and precipitation, fine coal slurry in the high-density material kaolin content is more high moisture, combined with the neighbourhood of the actual production of coal plant Combined with the actual production experience of neighbouring coal processing plants, the belt conveyor transport is easy to slip, and the ash content is high, which is not suitable for the coal slurry directly back to mixing the final coal product layout form, so the fine coal slurry recycling system of this coal processing plant is arranged in the form of a centralised integrated arrangement of the filter-pressing and recycling system and the coal slurry drying field.

4 Conclusion

1)The content of fine coal slurry is high in the coal processing plant of Bourdong coal mine, and the raw coal is easy to be sludged, so it is suitable to use the filter press recovery process to recover the fine coal slurry.

2)The fine coal slurry of Boerdong coal mine coal processing plant has the characteristics of high moisture, high ash, low ignition point, etc., the existing industrial site is narrow, the remaining space is small and scattered, and it is not possible to add new land, therefore, the fine coal slurry recycling system of the plant is arranged in the form of filter-pressing and recycling system, and the slurry drying field is centrally arranged in the form of a single unit, which not only can make full use of the existing site space and improve the competitiveness of the final coal products, but also can create good economic benefits for the coal processing plant. economic benefits for the coal processing plant.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses