filter pressFactory Contact:18851718517

Filter Press Filter Cloths Below are several types of filter press cloths:

- Polyester staple fibre filter cloth: acid-resistant, weak alkali resistant, abrasion-resistant, corrosion-resistant, good reversibility, very poor conductivity.

- Polyester long fibre filter cloth: smooth surface, good abrasion resistance, high strength, through twisting, higher strength and better abrasion resistance, thus the fabric has good air permeability, fast water leakage and easy cleaning.

- Polypropylene filter cloth: divided into polypropylene short fibre filter cloth and polypropylene long fibre filter cloth.

Filter press cloth has the advantages of fast filtration speed, good filtration effect, acid and alkali resistance, high temperature resistance, abrasion resistance, stretch resistance, etc. It is widely used in chemical, pharmaceutical, food, metallurgy, petroleum, environmental protection and other industries.

The principle of diaphragm filter press is that a layer of diaphragm plate is added between the filter plate and filter cloth of the filter press, and when the feeding is finished, high-pressure fluid or gas medium can be injected into the diaphragm plate, at which time the whole diaphragm will bulge up to press the filter cake and realise the further dewatering of the cake, which is also known as the press filtration. Diaphragm filter press has the advantages of high pressing pressure, good corrosion resistance, convenient maintenance, safety and reliability, etc. It is the replacement and upgrading equipment of ordinary chamber filter press and plate and frame filter press. Diaphragm Filter PressDiaphragm Filter Press is widely used in metallurgy, coal gas, papermaking, coking, pharmaceutical, food, brewing, fine chemical industry.

]]>- 將Filter Press Cloth其中的一塊卷成細長的形狀。

- 將濾布的兩面整理平整,并使系帶處于濾板的上方。

- 將系帶系好的濾布前后兩片平整的覆蓋濾板。

- 檢查濾布上的進料孔是否與濾板上的對齊。

- Testing constant pressure filtration constant and specific resistance: In the experiment, the constant pressure filtration constant and specific resistance are calculated by measuring the parameters such as filtration pressure, filtration time and mass of filtrate, so as to understand the performance of filtration media and filtration mechanism.

- Determination of the compression index of the filter cake under different pressures: By changing the filtration pressure and observing the compression of the filter cake, the compression index of the filter cake under different pressures is determined, so as to understand the structure and nature of the filter cake.

- Learning the method and operation of washing rate measurement: in the experiment, by measuring the washing rate, to understand the performance of the filter media and washing efficiency during the washing process.

- Observe the experimental medium flow state in the pipeline: through the experiments to observe the experimental medium flow state in the pipeline, to understand the rules and characteristics of the flow in the pipeline.

- Measurement of flow rate and pressure drop during filtration: Experimentally measure the flow rate and pressure drop during filtration to understand the performance and filtration effect of the filter.

- Understanding the structure, operation and maintenance methods of plate and frame filter press: through the experiment to understand the structure, operation and maintenance methods of plate and frame filter press, laying a foundation for the subsequent actual production.

- 檢查濾板是否對正,濾布是否干凈整齊、無褶皺。

- 壓緊濾板:壓緊油缸(或是其它的壓緊機構)進行工作,使動板向定板的方向進行移動,把兩者之間的濾板給壓緊。把相鄰的濾板構成一個封閉的濾室。

- 壓濾過程:給料泵(也就是隔膜泵)將礦漿輸送到濾室里,等到充滿后,壓濾工作開始,借助壓力泵或是壓縮空氣的壓力,進行固液分離的操作。

- 松開濾板:利用拉開裝置將濾板按照設定好的方式、設定好的次序拉開。

- 濾板卸料:拉開裝置相繼拉開濾板以后,濾餅就會借助自重脫落,由下部的運輸機將其運走。

- 清洗濾布:濾布原則每次出完泥后進行沖洗,也可以為每天一次。

board and frame typefilter pressFilter Press Cloth

- Resistant to acid, weak alkali, abrasion, corrosion, good reversion, very poor electrical conductivity.

- Smooth surface, good abrasion resistance, high strength, through the splicing and twisting, higher strength and better abrasion resistance, so that the fabric has good air permeability, fast leakage and easy cleaning.

- Polyester staple fibre filter cloth raw material structure is short and hairy, woven fabrics are dense, good particle retention, but stripping, poor air permeability.

- Nylon filter cloth nylon to fibre high strength, strength of 4-5.3Cndtex. elongation of 18%-45%. 10% elongation elasticity of the same rate of 90% above. Abrasion resistance is the highest among many kinds of fibres.

- Polypropylene filter cloth filter cloth classification: polypropylene to short fibre filter cloth; polypropylene long fibre filter cloth.

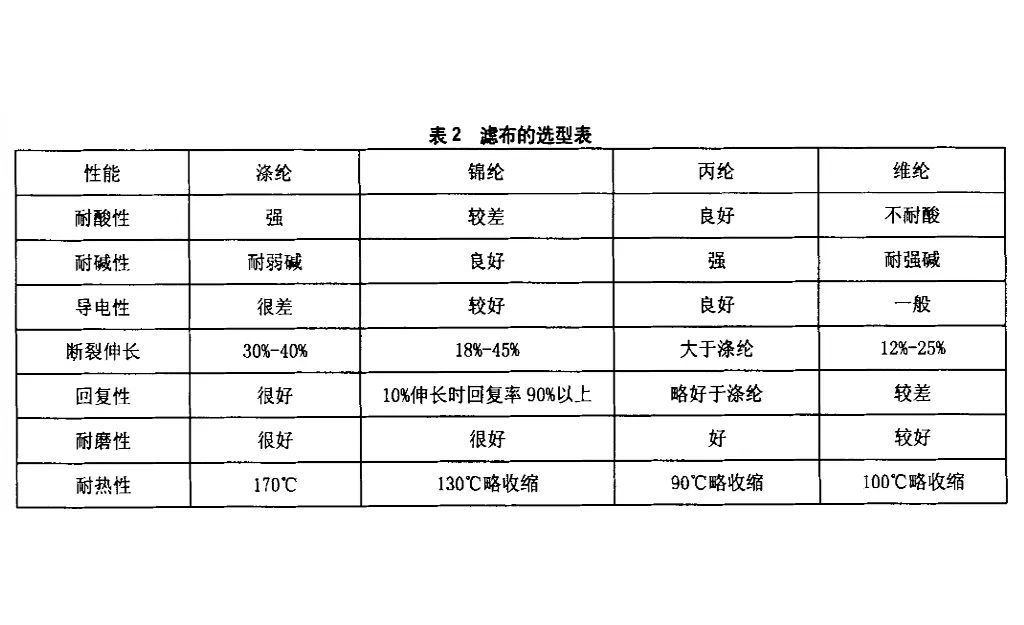

Filter press cloths are classified and selected according to the selected cloth material, the way the material is constructed, and the way it is prepared.

1.1.1 Polypropylene filter cloth

Polypropylene is a fibre made from propylene as raw material by polymerisation and melt spinning, which is cheaper. Polypropylene filter cloth has good chemical resistance, good resistance to acid and alkali, high mechanical strength, good abrasion resistance. The wet strength of polypropylene is basically equal to the dry strength, and the strength of polypropylene filter cloth basically remains unchanged in the process of filtration after feeding mud. Polypropylene filter cloth hygroscopicity is very small, almost non-hygroscopic, the general atmospheric conditions of the moisture return rate is close to zero, but it has a core suction effect, through the fabric in the capillary transmission of water vapour, but does not play any absorption role. The longitudinal surface of polypropylene is flat, straight and light, which also facilitates the stripping of sludge after sludge compression. However, polypropylene filter fabric has poor light resistance, poor thermal stability and is easy to age.

1.1.2 Polyester filter cloths

Polyester is a fibre-forming polymer - polyethylene terephthalate (PET) - made from purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG) by esterification or ester-exchange and polycondensation reactions, and then made into fibres by spinning and post-treatment. Polyester has high strength, good abrasion resistance, good light resistance, corrosion resistance, resistance to bleach, oxidants, cones, ketones, petroleum products and inorganic acids, resistance to dilute alkali, not afraid of mildew, but the hot alkali can be made to decompose.

Due to the low moisture absorption of polyester filter cloth, its wet strength is basically the same as its dry strength. The elasticity is close to that of wool, and it can be almost fully recovered when elongated 5%-6%. Wrinkle resistance exceeds that of other fibres, i.e. the fabric is not wrinkled and has good dimensional stability.

1.1.3 Nylon filter cloth

Nylon fibre high strength, strength of 4 ~ 5.3Cndtex, elongation of 18% ~ 45%. 10% elongation elasticity in the same rate of 90% to ± o nylon strength in the strongest fibres, it is measured, nylon fibre abrasion resistance of cotton fibre 10 times, 50 times viscose. Abrasion resistance is the first of a variety of fibres. Nylon fibre is resistant to strong alkali and weak acid. However, nylon is not resistant to light, easily discoloured and brittle, so nylon fabrics should not be exposed to sunlight for a long time.

1.1.4 Vinylon filter cloth

Vinylon filter cloth chemical name is called polyvinyl alcohol, its strength is lower than polyester, strength is only 3.52~5.72Cndtex. breaking elongation 12%~25%. elasticity is poor, the fabric maintains the shape of the poor, better abrasion resistance, durability is 1~2 times more than pure cotton. But there is a big advantage is able to withstand the role of strong alkali, and moisture absorption is good, easy to combine with the rubber, is a good material for the rubber industry, it is a disadvantage of lower temperature resistance, the temperature up to 100 dragons on the contraction of the acid is not resistant.

| a meter (measuring sth)1Performance indicators of different material filter clothsTab.1PerformanceofDifferentMaterial | ||||

| performances | polyester fibre | nylon | polypropylene fiber | (loanword) vinylon, synthetic fiber made from polyvinyl alcohol |

| acid resistance | vigorous | mediocre | favourable | acid-intolerant |

| alkali resistance | alkali-resistant | favourable | vigorous | alkali |

| responsiveness | an excellent | preferably | an excellent | mediocre |

| abrasion resistance | an excellent | an excellent | (of an unmarried couple) be close | preferably |

1.2 Filter cloth material structure

According to the structure of the filter cloth material can be divided into: monofilament, compound filament long fibre and staple fibre.

Monofilament is generally a synthetic fibre pulled into a single filament of 0.16-0.32dtex, the filter cloth woven by it has the advantages of smooth surface, uniform void, small specific resistance, fast water permeability, not easy to block, easy to clean and good sludge stripping performance. However, it traps particles of larger diameter, the filtrate has a higher solid rate and a lower recovery rate.

Compound filament, i.e. warp/weft, consists of multiple fibres woven into a single filament. Compound filament long fibre woven into filter cloth with it, good tensile strength, the retention of particles is better than monofilament, but the sludge unloading peeling performance is slightly worse.

Complex filament staple fibre is made of natural cotton wool fibre or synthetic staple fibre twisted into multiple strands, which has a fluffy fibre, presenting good particle retention performance, good sealing, but the disadvantage is that the pores are easy to clog, cleaning and sludge stripping performance is poor.

| a meter (measuring sth)2Characteristics of several common structural forms of filter cloths

Tab.2CharacteristicofServalCommonStructionFilters |

||

| material (that sth is made of) | filament | filament |

| polypropylene fiber | Polypropylene long fibre, the fibre is long, the formation of the yarn is smooth, and polypropylene long fibre woven into the industrial fabric, the cloth surface is smooth, breathable performance is good. | Polypropylene staple fibre, short fibre, spun yarn with hair; so polypropylene staple fibre woven into industrial cloth, cloth surface with hair, powder filtration and pressure filtration effect is better than long fibre. |

| polyester fibre | Polyester long fibre filter cloth has smooth surface, good abrasion resistance, high strength, higher strength and better abrasion resistance through twisting, thus the fabric has good air permeability, fast water leakage and easy cleaning. | Polyester staple fibre filter cloth raw material structure is short and hairy, woven fabrics are dense, particle retention is good, but peeling, air permeability is poor. Strength and abrasion resistance, water leakage is not as good as polyester long fibre filter cloth. |

1.3 Filter cloth preparation

According to the weaving method of filter cloth can also be divided into three kinds: plain, twill and satin.

Plain filter cloth has dense structure and small pores, so it has good particle retention, high filtrate clarification, long service life and cheaper price. The disadvantage is that the specific resistance is large, easy to clog, and the performance of slag discharge is poor.

Satin weave fabric has the largest pores, small specific resistance, not easy to plug, good sludge stripping performance. However, the particle retention capacity is low, the filtrate is turbid, and the recovery rate is low.

The performance of twill filter cloth is between plain and satin, but it is widely used because of its strong friction resistance, high filtration speed and longest life.

Requirements for filter cloth of plate and frame filter presses for urban wastewater treatment plants

Urban sewage treatment plant sludge production is larger, the work intensity is higher, the filter cloth is often used repeatedly extrusion, need to have a certain tensile strength, no stretch, good dimensional stability, the mechanical strength of the filter cloth requirements are higher; in the sludge conditioning and tempering process is often required to add PAM, iron salts, aluminium salts or lime and other agents, the sludge nature of the sludge is more complex, the sludge is alkaline after the conditioning, the filter cloth should be able to have a certain degree of Corrosion resistance.

Urban sewage treatment plant sludge is mainly organic particles, fine particles, the need for relatively small pore filter cloth, filtration filtrate to be clearer, conducive to improving the recovery rate of sludge; filter cloth permeability is also good, fast filtration speed, faster discharge of water out of the sludge, to improve the efficiency of the plate and frame machine; filter cloth should not be clogged; filter cloth dewatering of sludge after the stripping of the good, the mud cake in the plate and frame machine can be automatically stripped after the opening of the frame; easy to rinse the regeneration, to extend the use cycle, reduce the cost of using the cloth. The filter cloth is easy to be washed and regenerated, which prolongs the use cycle and reduces the use cost.

Therefore, in the plate and frame filter press cloth selection, to be able to meet the following requirements: high strength, corrosion resistance, filtrate clear, fast water permeability, not easy to plug, easy to peel, long life.

3Analysis of test data

According to the actual processing experience, for the above requirements, combined with the characteristics of the material, urban wastewater treatment plant plate and frame filter press dewatering machine filter cloth should be used for polypropylene or polyester filter cloth, the material composition of the selection of monofilament or filament filament long fibre, the preparation of choice of commonly used twill pattern, and will be the two kinds of filter cloth for testing and comparison, as shown in Table 3.

| Filter cloth number | material (that sth is made of) | framework | Presentation |

| 1# Filter Cloth | polypropylene fiber | multifilament long fiber | twill |

| 2# Filter Cloth | Polyester Unity; | monofilament | twill |

A plate and frame filter press with a filtration area of 4 n? was used in the test, the maximum pressing pressure was 15 kgf and the maximum closing pressure was 12 kgf, and two types of filter cloths as shown in Table 3 were used to analyse the sludge treatment under the conditions of different concentration of chemicals and different types of chemicals.

The sludge used for the test was the thickened sludge from the Shidongkou Sewage Treatment Plant, and the chemicals used were fly ash from sludge drying and incineration, ferric chloride and cationic polyacrylamide.

3.1 Effect of different agents on the water content of filter fabrics

The test selected the common types of chemicals added, combined with the selection of plate and frame filter presses under different filter cloth conditions, water content and other conditions of the analysis," as shown in Table 4.

| batches | Water content of feed mud/% | Proportion of dosage | press-fit (e.g. seam sealing) | extract juice, oil etc by squeezing | –Cloth_Filter Type– | Cake moisture content

/% |

||||

| fly ash

/% |

carnallite (hydrated potassium magnesium chloride mineral)

/% |

PAM

(+)/% |

Pressure/kgf | Time/min | strains

/kgf |

Time/min | ||||

| 1 | 97.2 | 10.0 | 0 | 0.015 | 11.5 | 90 | 15 | 60 | 1# Filter Cloth

2# Filter Cloth |

78.1

79.7 |

| 2 | 97.3 | 0 | 7.0 | 0 | 11.5 | 90 | 12 | 60 | 1# Filter Cloth

2# Filter Cloth |

69.6

68.5 |

| 3 | 97.1 | 20.0 | 8.0 | 0.014 | 11.5 | 90 | 12 | 60 | (Cant.) plural for pronouns

2 luminescent cloth |

65.9

65.3 |

From the water content of the mud cake, without adding iron salt, the water content of the mud cake of 2# filter cloth is higher than that of 1# filter cloth, and after adding iron salt, the water content is obviously reduced, and the water content of 2# filter cloth is lower.

3.2 The effect of different dosage on the water content of the filter cloth

The test selected in the iron salt dosage fixed, fly ash dosage changing conditions, two filter cloth filtration after the water content of the situation shown in Table 5.

From Table 5, it can be seen that due to the better water permeability of the 2# filter cloth, the reduction of water content is particularly obvious with the increase of the concentration of fly ash injection.

| batches | Water content of feed mud/% | Proportion of dosage | press-fit (e.g. seam sealing) | extract juice, oil etc by squeezing | -Types of filter cloth | Cake moisture content

/% |

||||

| fly ash

/% |

carnallite (hydrated potassium magnesium chloride mineral)

/% |

PAM

(+) |

strains

/kgf |

Time/min | Pressure/kgf | Time/min | ||||

| 1 | 97.0 | 25.0 | 7.0 | 0 | 11.5 | 90 | 12 | 60 | 1# Filter Cloth

2# Filter Cloth |

65.1

65.2 |

| 2 | 97.4 | 30.0 | 7.0 | 0 | 11.5 | 90 | 12 | 60 | 1# Filter Cloth

2# Filter Cloth |

57.5

55.9 |

| 3 | 97.1 | 45.0 | 7.0 | 0 | 11.5 | 85 | 12 | 60 | 1# Filter Cloth

2# Filter Cloth |

53.5

52.1 |

3.3 Comparative analysis

Combining the above test results, a comparative analysis of the two filter cloths is shown in Table 6.

| a meter (measuring sth)62Indicators for the evaluation of filter clothsTab.6Performanceof2Filters | ||

| Evaluation indicators | 1# Filter Cloth | 2# Filter Cloth |

| Dehydrated moisture content | your (honorific) | lower (one's head) |

| turbid filtrate | surname Qing | impure |

| Automatic shedding | differ from | (of an unmarried couple) be close |

| permeability | (following a decimal or fraction) slightly less than | vigorous |

reach a verdict

With the growth of urban population, the continuous improvement of municipal services, sewage treatment technology innovation and the deepening of the degree of treatment, the amount of sludge produced in the process of sewage treatment will increase greatly, sludge dewatering and reduction is imperative, plate and frame machine as a more commonly used treatment equipment, the development prospects are broader.

The selection of filter cloth for plate and frame machine is very important, which needs to be considered comprehensively with a number of factors such as filtrate, water content of sludge cake, and the cost of use, etc. While summarising the nature of sludge and the characteristics of the treatment process of municipal sewage treatment plant, two commonly used filter cloths were selected for the experimental study, and the results showed that the polyester monofilament twill filter cloth was able to get a lower water content, but the filtrate was more turbid, and the recovery rate of the sludge dewatering was lower, while the Polypropylene compound filament twill filter cloth has a higher water content, but the filtrate recovery is good. Each sewage treatment plant can choose the appropriate filter cloth according to its own situation, to achieve the purpose of reducing the water content and improving the efficiency of use.

Technical: 188517-18517

E-mail: suton@su-ton.com

]]>The filter cloth of filter press mainly includes: polyester filter cloth, polypropylene filter cloth, nylon filter cloth, polyvinyl chloride filter cloth and other kinds of filter cloth. Here we will introduce how to correctly install the filter cloth on the filter plate of the filter press.

1. Tighten the filter cloth clamps.

2. Hang the filter cloth on the filter plate and keep the surface of the cloth flat.

3,Filter Press ClothThe cloth grippers pass through the inlet holes of the filter press plate from both sides.

4.Tighten the cloth clamp;

5. Check whether the feed holes on the filter cloth are aligned with those on the filter plate.

6. Roll one of the filter cloths into a thin (tube) shape and then wear the inlet in the middle of the filter plate.

7, the two sides of the filter cloth will be arranged flat, and make the tie at the top of the filter plate, the front and rear pieces of the filter cloth tied with the tie will cover the filter plate flatly.

How to fit the first filter cloth of a filter pressCaveats:

1, the filter cloth around the filter plate pressing contact part should ensure flat, can not produce wrinkles, to avoid being squeezed by the filter plate filter cloth caused by damage or mud leakage.

2, to avoid the grommet tail is too long may reach into the part of the filter plate press fit and damage the filter cloth, or cause mud leakage, should cut off the short tail.

3, installation, need to pay attention to the filter cloth and filter plate between no foreign objects or larger sludge particles, larger sludge particles or foreign objects may be in the plywood, causing damage to the filter plate or filter cloth.

4, the installation of filter cloth should pay attention to the front and back (to the mud surface and non-mud surface), generally no special requirements, the cloth of the filter cloth (polished surface) to the mud. Otherwise, the wrong installation will result in easy blockage of the filter cloth and low filtration efficiency.

5、Don't lock the filter cloth too tightly with the grommet, otherwise the residual sludge in the filter cloth in the contact part of the filter plate pressing will not be removed by automatic cleaning.

6, spare filter cloth should be stored in a cool and dry place, it is recommended to use a dark shade cloth to be protected, to avoid ultraviolet radiation, to prevent the aging of the filter cloth material.

7, before installing the filter cloth, it is necessary to install the supporting filter cloth, whose function is to minimise the abrasiveness of the cloth being rapidly detached from the filter cake downward due to gravity and possibly rubbing the bumps on the surface of the filter plate when discharging sludge, in order to protect the filter filter cloth, prolong the service life of the filter cloth and enhance the filtration effect.

8, filter press filter cloth after cleaning, to hang to dry, temporarily not used filter cloth should also be placed in a cool, dry place, there are dark shade cloth to protect up, not be able to be the sun has been direct sunlight, otherwise the filter press filter cloth is easy to aging.

]]>

Plate and frame filter pressIt is an intermittent filter press with a long history but still in use, which is widely used in environmental protection, chemical industry, coal, petroleum, food, pharmaceuticals and other industries, in the existing suspension mixture separation equipment, according to its ease of operation, cost and cost, the effect of de-liquefaction and other factors of comprehensive economic value.Plate and frame filter pressIt is one of the best separation equipment, which belongs to intermittent pressurised filter, with the advantages of compact structure and large filtering area, mainly used for filtering suspension with much solid content, because it can withstand high differential pressure, its operating pressure is generally 0.3-1.0MPa, so it can filter fine particles or materials with high liquid viscosity, it is one of the simplest and most widely used models in the pressurised filter structure at present [1]. With the country's increasingly high requirements for environmental protection and resource utilisation in all walks of life, the need for energy saving, emission reduction, cleaner production and green manufacturing is becoming more and more urgent. Plate and frame filter press, as the main equipment used in the field of environmental protection applications, is expected to have a substantial increase in market demand under the premise of increasingly high environmental protection requirements.

1.Plate and Frame Filter Press Patent Overview This paper is based on the patent data related to plate and frame filter press, and the search covers the global invention patent applications before May 2020 in the CNABS, DWPI, CNTXT, WOTXT, EPTXT, and USTXT databases, and the data after November 2018 is for reference only, as the patent applications may need to be published 18 months later. By combing the foreign patent applications for plate and frame filter presses, their changes in filing volume over the years and the main applicants. As can be seen from the foreign patent applications distributed by years, the foreign research on plate and frame filter press is relatively early, and the research in this field began at the end of the 18th century, and the number of patents filed before the 1960s is relatively small, but after the 1960s the growth momentum of applications is obvious, and the number of applications for this device reached a peak in the 1980s, and then slowly declined, and then reached the second at the beginning of the 21st century A small peak was reached in the early 21st century, followed by a spurt in 2012 and a decline in filings in recent years. In terms of the ranking of the number of applications, Otto Tec and JVK Filtration Systems occupy the top two positions, and the number of applications is more than twice that of Otto Kump, which is in the third position. As shown in Figure 3, through combing the sources of global patent applications, it is found that the patent applications in this technology field are mainly concentrated in China, accounting for 38% of the global application volume, followed by Germany, the United Kingdom, France and other European countries, and the United States also has a larger proportion of patent applications, Europe is thePlate and frame filter pressesThe earliest place of use, in Germany, France, the United Kingdom is widely used in the coal industry, chemical industry, medical and other filtration industries, after more than one hundred years of development, a new generation of plate and frame filter presses have appeared one after another, and the level of technology continues to improve.

The domestic plate filter press started late, and the overall level of applications was low in the 20 years from 1986 to 2006, and entered a period of rapid growth from 2007, and the annual application volume reached more than 140 in 2018, and the data in 2019 declined due to the impact of the patent publication cycle. It can be seen that the applicants in China have been continuously focusing on the technological research and development of plate and frame filter press. The main applicants of the top ten domestic patent applications. It can be seen that the main body of applicants in China is mainly companies, and research institutes and universities pay less attention.

2.Plate and frame filter press technology development route Plate and frame filter presses first appeared in Europe, in Germany, France, the United Kingdom in various industries, plate and frame filter presses are widely used, including coal, chemical, medical, textile and other fields. Over the years, the plate and frame filter press has been continuously developed and improved, and its structure has gone through many generations of changes, and the level of technical application has also been greatly improved. The development of plate and frame filter press can be divided into four stages:

(1) the first generation of plate and frame filter press in 1910, Britain invented the plate and frame type filter press, which sets the filter material in the plate and frame, and filters the slurry by squeezing the filter plate, but there is still a lot of water left in the filter cake, which is about 20%-22%. in the same year, the GB191026231A further proposed the improvement of the filter press plate, so that the metal plate has a pair of metal mesh fixed to the two sides by the wooden bar, and these wooden bars into a pair of metal mesh with serrated joints, and a conical plug is set in the drain slot of the bottom bar, which is fixed by screws or bolts on the tray, the metal buttons or washers. of a pair of wire meshes which are formed with serrated joints, with conical plugs in the drainage slots of the bottom bars, and with the trays strengthened by fixing strips of wood, metal buttons or washers to the trays by screws or bolts.In 1912 in GB191223867A it was proposed that the grates be constructed so as to have passages forming channels substantially parallel to the circumferences or sides of the passages, which passages are partitioned so as to provide perpendicular passages for air intake or exhaust. Filter presses of this generation have localised pressurisation, and so show significant advantages in the dewatering of suspensions of fine particle size and high viscosity. However, there are still problems such as long filter press time, high operating cost with small capacity, high consumption of filter cloth, short life of filter plate, intermittent production and high maintenance.

(2) The second generation of plate and frame filter presses made structural improvements to address the shortcomings of the first generation of plate and frame filter presses, and in GB2282722A proposed an improvement to the filter plate frame by supporting the edges of strips of paper or very thin filter media on both sides of the frame, with the filtrate flowing through channels formed in the bottom frame strips of the frame, or through slots cut in the strips; in 1930, GB346191A proposed further drying of the filter cake by suspending hollow heating elements in the frame, followed by a series of patent applications in the area of heating the filter cake; in 1953, GB718801A proposed to provide the hollow portion of the filter plate with gripping means having, at least on its edges, spacer surfaces comprising spacer surfaces capable of springing open and engaging on opposite sides of the edges of the apertures, the ports being fitted into the edges of the apertures to hold said portion in the plane of the plate, permitting easy removal thereof; in 1960, GB905098A proposed a filter plate of the type of housing structure for filtration with the aid of a filter aid; improvements during this period include filter plate construction (DE881639C, DE940527C, US2594518A), filter plate material (GB909045A), multiple feeds, filter plate support ( GB797880A, GB820668A), hydraulic cylinders, pull-open devices and automation, but also added a second pressing, that is, before the opening of the plate unloading to add a mechanical pressing process with a relatively short process time, further reducing the moisture in the filter cake.

(3) The third generation of plate and frame filter presses was introduced in Germany in 1969 in DE1960821B with diaphragm-type filter plates, i.e., each plate has a filter membrane with a slotted backside to form a filtrate channel between the plate and the membrane, and a sludge chamber or wall of a next door on the other side. The membranes are rolled down to fit over the edges of the plates and locked into the separating plane between neighbouring filter banks. In this plate mode, when the slurry fills the filter chamber, high-pressure air is pressed into the interlayer between the membrane and the plate, and the elasticity of the membrane is used to squeeze and dewater the cake, while a "blowing" process is used to replace the filtrate in the cake void with air to reduce the moisture in the cake again. 1980, Kurita Machinery Co. In 1980, in order to improve the dewatering rate of the filter cake, Kurita Machinery Manufacturing (JPS5794312A) in Japan ensured the passage of filtrate by providing a gap between the concave portion of the filter-pressing membrane and the open portion of the vertical holes, and the patent applications relating to diaphragm-type filter presses from the 1870s to the 1890s were very active and were mainly located in Germany, Japan, the United Kingdom, and the United States. The plastic diaphragm filter plate with filter cloth on both sides of the filter plate, when filled with high pressure gas for pressing, the diaphragm can fully press the filter cake, with less dead space and good pressing effect.

(4) the fourth generation of plate and frame filter press Sarah company designed the VP type filter press uses another form of "blowing process", after the "extrusion process" of the cake, the space between the particles and a certain amount of water, it can be assumed that the space between the particles for the length or diameter of different capillaries. or different diameter capillary, these capillary filtrate is very difficult to discharge through the "extrusion process". Therefore, the procedure of "blowing" was adopted to replace the filtrate in the gaps with pressurised air. When the pressurised air enters the capillary tubes of the filter cake, the liquid therein is gradually replaced by the air, and the moisture content of the cake will be reduced. In this process, the Chinese applicant has also proposed a series of improvements on the basis of the existing filter press, for example, for the defects in the diaphragm filter press in which the diaphragm ruptures after a long period of time, the whole operation process is long, and the sludge discharge requires one plate and one plate to be moved sequentially, it was proposed in CN102068840A in 2010 that there is an elastic press frame between the two filter plates, and that the elastic press frame forms a seal between the elastic press frame and the filter plate; South China University of Technology proposed in CN108465278A a high-pressure plate and frame filter press with retractable filter plates. Aiming at the problem of high water content of filter cake, a series of proposals on plate and frame filter presses with backblowing air drying are put forward, wherein each filter press plate is provided with an air guide pipe made of soft material, and the air inlet hole is connected to a high-pressure air pipe provided above the filter press through the air guide pipe to reduce the water content of the material to 181 TP3T-221 TP3T.

3.Outlook Plate and frame filter press belongs to an important part of solid-liquid separation equipment, and its development process in Europe has experienced more than a century. Although our patent system started late, so the patent application about plate and frame filter press is also relatively late, but the domestic researchers have summarised the existing technology well, put forward a series of improvements for the shortcomings of the existing technology, and the number of patent applications has been growing, which promotes the rapid development of China's filter press technology, and its patent protection network will also be more and more perfect.

Disclaimer: The copyright of this article belongs to the original author and the original source. Welcome to call us for consultation, technical exchanges, and material experiments.

]]>filter pressAs a mature dewatering equipment, it is widely used in the field of environmental protection, becoming an important equipment for sewage sludge treatment, mainly used for solid-liquid separation of all kinds of sludge sludge, which can be applied to solid-liquid separation of water treatment process in various industries, sludge drying treatment process, greatly improving the efficiency of sewage treatment and reducing the discharge of waste.filter pressRoughly can be divided into chamber filter press, belt filter press and plate and frame filter press. Yixing China Resources Thermal Power Co., Ltd. 2 × 60MW unit was put into operation, the company's wastewater treatment process using coagulation and precipitation of sludge after drying treatment, the main source of sludge for the desulfurization system and ash system, sludge drying equipment using manually reinforced polypropylene chamber filter presses, the daily amount of drying sludge for 12 tonnes, the sludge filtering process of the normal operation of wastewater treatment system plays a decisive role. 2 chamber filter presses The working principle of chamber filter press is a solid-liquid separation equipment integrating machine, electricity and liquid, mainly composed of frame, filtering part, hydraulic part and electric part.

The frame is the basic part of the filter press, the two ends are the thrust plate and the pressing head, both sides of the beam will be connected to the two, the beam is used to support the filter plate, the filter frame and the pressing plate: the hydraulic part of the pressing mechanism consists of a hydraulic station, cylinder, piston, piston rod and piston rod and the pressing plate connection; the filtration part consists of the filter plate, the filter frame, the filter cloth, the press diaphragm, the two sides of the plate by the filter cloth cover; the electrical part consists of the hydraulic station, the pull plate device, the chain drive device. The electrical part is composed of hydraulic station, pulling plate device and chain transmission device. The working principle of chamber filter press is as follows: when the pressing machinery presses, high pressure oil is supplied by the hydraulic station, and the pressing plate slowly presses the filter plate, when the pressing force reaches the pressure value set by the relief valve, the filter plate is pressed, and the relief valve starts to unload, at this time, the power supply of the motor is cut off, and the pressing action is completed, and when the pressure is kept automatically. The filtrate is transported to the filter chamber inside the filter plate of the filter press by the sludge pump, and each filter plate is equipped with a water nozzle on the lower outlet hole, and the filtrate intuitively flows out from the water nozzle, and the filter chamber consists of concave-convex filter frames, and the filter cloths are fixed to the plate frames. The sludge is kept inside the filter chamber, and when the filtering pressure increases, the sludge inside the chamber is pressed into mud cake. The main advantage of chamber filter press is that it is easy to replace the filter cloth, and the disadvantage is that the filter plate is easy to be damaged. Yixing Huarun Thermal Power Co., Ltd. wastewater system chamber filter press model ) (MZFl25 / 920 a UB, originating from Hangzhou, Zhejiang Province, the filter plate is made of polypropylene, the filtration area of 125m2, the current operating conditions are good.

Analysis of common faults in the use of chamber filter presses

Damage to the filter cloth The holding pressure of the electrical pressing parts of the chamber filter press is maintained at 20 MPa. Sludge transfer pump conveying pressure is usually 0.5-0.8Mpa, in the filter press filtration process, the sludge dewatering rate in the filter chamber will be higher and higher, and the filter cloth filter eyes with the decline in filtration capacity and blockage, under the pressure of the material transfer pump, easy to make the filter cloth damage. At the same time, the selection of filter cloth and the quality of processing also plays a key role in the service life of the filter cloth. Filter cloth is usually divided into polyester, cotton, nylon and other materials, the performance of different filter cloth on the pH value of wastewater, solid content size and other indicators of the degree of adaptability, and the filter press operating results of the most important selection of the appropriate filter cloth, such as the selection of the inappropriate filter cloth will appear in a short period of time broken filter cloth, filtering channel clogging, sticking to the board and other issues.

The most critical indicators of the service life of the filter cloth are the characteristics of the filter medium and the quality of the filter cloth, in addition to selecting the filter cloth suitable for the nature of the filter medium, the quality of the filter cloth is also the most important indicator of the impact of filtration effect, the new filter cloth should be checked before the installation of the surface of the filter cloth whether there are scratches, whether the cloth is aging, and check the filter cloth stitching line whether the needle is off or whether the stitching is too large. After 70 rows of filter cloth, we need to pay attention to whether the filter cloth expansion and contraction leads to the rupture of the filter cloth, the stitching line is disconnected and the pinhole gap is increased. The stitching line pinhole is very easy to become bigger after the filter cloth is compressed and stretched, and the bigger pinhole will directly reduce the filtering effect.

For our wastewater system in the existence of a larger amount of sludge, pH value is lower, the required telescopic requirements of higher requirements for the filter material requirements, after a trial selection of polyester material, its high strength, water permeability is good. The service life can reach more than 2400 hours, sludge sticky cloth performance is good.3.2 Pulling the plate mechanism failure filter press pulling the plate mechanism is one of the most frequent use of the filter press, mainly used for unloading operation of the filter plate, prone to failure phenomenon. The most common failures are: the robot can not pull the filter plate, the two sides of the robot is not synchronised, pulling the plate chain jams, mechanical fingers can not be popped up and so on. The main solutions are: pull the plate motor friction plate is tight enough, but when the loose pull the plate motor friction plate has been enhanced pull the plate manipulator pull, but the friction plate can not be adjusted too loose, the manipulator pull too much will make the polypropylene filter plate puller damage; manipulator is not synchronised with the need to adjust the proximity switches, travel switches and pull the height of the plate chain; pull the plate chain astringent need to timely maintenance of the pull the plate chain, the pull plate chain due to acid water corrosion of the chain pitch, the pull the plate chain is not easy to maintain. Acidic water corrosion chain pitch is very easy to corrosion jams lead to normal drive; at the same time, pull the plate manipulator rollers and springs also need to strengthen the maintenance, found that the spring breaks need to be replaced in a timely manner spring.

Routine maintenance of filter presses

Cleaning of filter clothThe effect of filter press operation mainly depends on whether the filter cloth filtration is smooth. Whether the mud biscuit degree is good, which requires the filter cloth in the use of a certain period of time after the cleaning, because the filter cloth in the use of the process of filtering the eyes will be longer with the running time and blockage, resulting in a gradual decline in the filtration capacity of the filter cloth. The selection of filter cloth should refer to the filter sludge characteristics, pH value, sludge transport volume and other parameters to determine the type of filter cloth.

Running parts of the maintenance of the filter press in the use of the process, the need for lubrication of moving parts, moving parts are mainly for the pull plate chain, piston rod, roller, flap bearings, pulling the plate manipulator and springs, etc.; due to the process of cleaning the filter cloth, the water spray will have a direct impact on the surface of the parts of the filter press, is very easy to cause corrosion, the press filter in the normal operation of the parts need to be kept dry.

Filter plate cleaning hydraulic system maintenance often check the sealing surface of the filter plate to ensure that it is clean, clean, use the filter cloth to check whether the filter cloth is folded to ensure that it is flat and intact. Maintenance of the hydraulic system is mainly on the hydraulic cylinder tank level, hydraulic components and each of the various connection port sealing inspection and maintenance, while ensuring the cleanliness of the hydraulic oil.

Filter press operation control

Inspections before the use of the filter press to check whether the filter plate is damaged, whether the filter plate is clean, and whether the placement meets the requirements: check whether the filter cloth is folded, whether there is any damage, and whether the filtration performance is good: check whether the various lubrication and cooling equipment is in line with the requirements of the drive; check whether the connections are tight, and whether there is any leakage: check whether the oil pressure of the filter press is sufficient, and whether the oil level is in line with the requirements; test the pH value of the filter press feed sludge to see whether the pH value of the filter press is suitable.

Filter press process control After starting the pressing device, the filter press enters the automatic pressure preservation state, and the progress of filter press is controlled when filter press starts. Check whether the filter nozzles are smooth, and there is no gap between the filter plates and no sludge leakage. Check the filter plate with turbid water, stop filtering if necessary to check whether the filter cloth is broken, and repair or replace it in time if it is broken.

Unloading process control When the feed pressure is close to the sludge pump conveying pressure, and the water output from the filter plate nozzle becomes obvious, the unloading conditions are already in place. The pressure plate piston can be back in place, start pulling the plate trolley to start unloading. After unloading, check whether the filter cloth is neat and intact, such as filter cloth residues of adhesive sludge need to clean or replace the filter cloth.5.4 Filter press operation precautions:

When the filter press is holding pressure, it must ensure that the filter plate is flat, there is no debris between the filter plates, and the filter cloth is even. As the pressure of the filter press will reach 20MPa when it is holding pressure, such as the unevenness of the filter plate of the filter press will easily lead to bending and damaging the axle of the pressing device and damaging the filter plate during the process of holding pressure, meanwhile, the debris of the filter plate can make the sludge pump leak during the operation of the sludge pump, so that the filtration press operation cannot be carried out.

Filter press in the pressure, the feed pressure must be controlled in the factory nameplate marked on the maximum filtration pressure (gauge pressure) below, otherwise it will affect the normal use of the machine; 5.4.3 filtration began, the feed valve should be opened slowly, at first the filtrate tends to be more turbid, and then clear, is a normal phenomenon; 5.4.4 in the rinsing of the filter cloth and the filter plate, pay attention to do not let the water splash to the oil tank power supply:

When carrying and replacing the filter plate, the force should be appropriate to prevent collision damage, and it is forbidden to drop or hit, so as not to rupture the filter plate/frame. The position of the filter plate should not be put in the wrong place; do not take down the filter plate without authorisation when filtering, so as to avoid accidents due to insufficient stroke of the cylinder; after the rupture of the filter plate, it should be replaced in time, and should not continue to be used, otherwise it will cause the rupture of other filter plates;

If the equipment is not used for a long time, the filter plate should be cleaned and the filter cloth should be cleaned and dried.

reach a verdict

Filter press can be widely used in coal-fired thermal power plant water treatment process of sludge drying process, its sludge dewatering effect can be comparable to the dewatering machine, and lower investment costs, operation and maintenance is relatively simple. Yixing China Resources Cogeneration Co., Ltd. wastewater treatment system using chamber filter press process, sludge drying effect is good, filter drying after the sludge cake forming rate of 100%, the water content is usually 30%, solid-liquid separation effect is obvious. Therefore, for the sludge characteristics of sewage treatment production, select the corresponding filter press can also achieve better dewatering efficiency and sludge treatment capacity, at the same time, the operation of the filter press in the routine maintenance and maintenance of the importance of the filter press can not be ignored.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

]]>