在工業(yè)生產(chǎn)中,高效過(guò)濾是提升產(chǎn)能、降低成本的關(guān)鍵環(huán)節(jié)。蘇東壓濾機(jī)憑借先進(jìn)工藝與匠心品質(zhì),為各行業(yè)提供穩(wěn)定、耐用、智能化的過(guò)濾解決方案,助力企業(yè)實(shí)現(xiàn)綠色高效生產(chǎn)!

為什么選擇蘇東壓濾機(jī)?

??卓越性能——采用高強(qiáng)度聚丙烯濾板,耐腐蝕、抗變形,過(guò)濾效率提升40%,確保長(zhǎng)期穩(wěn)定運(yùn)行。

??節(jié)能降耗——優(yōu)化液壓系統(tǒng),能耗降低35%,運(yùn)行成本更低,符合現(xiàn)代企業(yè)節(jié)能需求。

??智能控制——配備全自動(dòng)PLC控制系統(tǒng),支持遠(yuǎn)程監(jiān)控、故障報(bào)警,操作更便捷,減少人工干預(yù)。

??廣泛適用——適用于礦山尾礦、化工污泥、食品發(fā)酵、環(huán)保污水處理等領(lǐng)域,滿足不同工況需求。

??定制服務(wù)——根據(jù)客戶實(shí)際需求,提供濾板材質(zhì)、過(guò)濾面積、自動(dòng)化程度等個(gè)性化配置,精準(zhǔn)匹配生產(chǎn)要求。

蘇東壓濾機(jī),助您輕松應(yīng)對(duì)嚴(yán)苛過(guò)濾挑戰(zhàn)!

無(wú)論是高粘度物料,還是高精度過(guò)濾,蘇東壓濾機(jī)都能以更低的能耗、更高的效率完成任務(wù),讓生產(chǎn)更順暢,成本更可控!

立即聯(lián)系Sudong Filter Press Manufacturer,獲取專屬技術(shù)方案!

核心關(guān)鍵詞:蘇東壓濾機(jī)、高效壓濾機(jī)、固液分離設(shè)備、工業(yè)過(guò)濾機(jī)、智能壓濾機(jī)廠家、污泥脫水設(shè)備、化工壓濾機(jī)

]]>- 自動(dòng)化程度高:選煤用快開隔膜壓濾機(jī)采用先進(jìn)的控制系統(tǒng)和自動(dòng)化設(shè)備,能夠?qū)崿F(xiàn)自動(dòng)化控制和操作,提高生產(chǎn)效率和降低人工成本。

總之,選煤用快開隔膜壓濾機(jī)是一種專門針對(duì)煤炭行業(yè)選煤過(guò)程特殊設(shè)備,具有高效、自動(dòng)化程度高、濾餅含濕量低等特點(diǎn),能夠滿足不同行業(yè)的需求。

開隔膜壓濾機(jī)是一種先進(jìn)的壓濾機(jī)設(shè)備,具有過(guò)濾效率高、操作簡(jiǎn)便、處理能力大等優(yōu)點(diǎn)。其特點(diǎn)包括隔膜壓榨過(guò)濾、低壓過(guò)濾和高壓沖洗1.

快開隔膜壓濾機(jī)的過(guò)濾過(guò)程是通過(guò)油缸體內(nèi)的活塞推動(dòng)壓緊板實(shí)現(xiàn)的,將位于壓緊板和止推板之間的濾板和過(guò)濾介質(zhì)壓緊,以實(shí)現(xiàn)固液分離。同時(shí),快開隔膜壓濾機(jī)還能夠根據(jù)設(shè)定的程序自動(dòng)完成過(guò)濾、壓榨、吹干等操作,并能夠自動(dòng)檢測(cè)濾板的滲漏情況,進(jìn)行清洗或更換。

快開隔膜壓濾機(jī)已被廣泛應(yīng)用于需要固液分離的各個(gè)領(lǐng)域,如煤炭、涂料、食品、化學(xué)藥品、食用油、污泥污水等。其多樣化的濾布類型和材質(zhì),能夠適應(yīng)不同物料的過(guò)濾需求,具有較好的通用性和適應(yīng)性。

]]>不銹鋼壓濾機(jī)的工作原理是:通過(guò)壓力將漿料壓入濾腔,使液體通過(guò)濾布流出,固體被截留在濾腔中,形成濾餅,從而達(dá)到過(guò)濾的目的1.

不銹鋼壓濾機(jī)的優(yōu)點(diǎn)有1::

- 耐腐蝕:不銹鋼材質(zhì)具有較好的耐腐蝕性,能夠適應(yīng)各種酸堿環(huán)境。

- 過(guò)濾效果好:不銹鋼壓濾機(jī)采用多層濾布,過(guò)濾效果更好。

- 適用范圍廣:不銹鋼壓濾機(jī)適用于化工、制藥、食品、釀造、冶金、石油、環(huán)保等領(lǐng)域。

- 易于清洗和維護(hù):不銹鋼壓濾機(jī)采用不銹鋼螺桿泵進(jìn)行清洗,方便快捷。

- 壓緊濾板:液壓系統(tǒng)操作,使尾板朝著頭板移動(dòng),按壓頭板和尾板之間的所有濾板,形成中空的密封過(guò)濾室。

- 壓濾過(guò)程:進(jìn)料泵將泥漿從尾板的進(jìn)料孔輸送至過(guò)濾室,泥漿在給料泵壓力的幫助下進(jìn)行固液分離。

- 松開濾板:液壓系統(tǒng)操作,將頭板返回原始位置。

- 濾板卸載:濾板由下輸送機(jī)運(yùn)走。

- 清洗濾布:每次出完泥后進(jìn)行沖洗,也可以每天一次。

洗煤設(shè)備包括:

- 重選設(shè)備:重介質(zhì)分選機(jī)、重介質(zhì)旋流器。

- 浮選設(shè)備:浮選機(jī)、浮選柱、浮選床、礦漿預(yù)處理器。

- 脫水設(shè)備:離心機(jī)、加壓過(guò)濾機(jī)、壓濾機(jī)、脫介篩。

- 其他設(shè)備:磁選機(jī)、空氣干燥機(jī)、空壓機(jī)、泵、弧形篩、皮帶、刮板機(jī)、分級(jí)旋流器、TBS、干擾床、螺旋分選機(jī)、跳汰機(jī)。

- 結(jié)構(gòu):隔膜式壓濾機(jī)由隔膜、膜板和濾布組成,形成了多個(gè)濾室,濾液和固體通過(guò)隔膜進(jìn)行分離;板框式壓濾機(jī)由濾框和濾板構(gòu)成,濾布被夾在濾框和濾板之間,形成多個(gè)濾室,固體被濾板支撐,濾液通過(guò)濾布流出。

- 操作方式:隔膜式壓濾機(jī)的操作一般較為自動(dòng)化,可以通過(guò)控制系統(tǒng)實(shí)現(xiàn)自動(dòng)控制和監(jiān)測(cè);板框式壓濾機(jī)的操作相對(duì)較為簡(jiǎn)單,通常需要手動(dòng)操作。

- 適用范圍:隔膜式壓濾機(jī)適用于過(guò)濾難度較大的懸浮液,如高濃度酒精、淀粉、動(dòng)植物蛋白等;板框式壓濾機(jī)適用于過(guò)濾懸浮液中含有大量固體顆粒或纖維的場(chǎng)合,如陶瓷、制糖、制藥等行業(yè)。

- 操縱能力:隔膜式壓濾機(jī)可以在過(guò)濾和壓榨階段調(diào)整進(jìn)料流量、壓力等參數(shù),靈活性較高;板框式壓濾機(jī)一般無(wú)法調(diào)整過(guò)濾過(guò)程中的壓力和流量,操作相對(duì)固定。

- 處理能力:隔膜式壓濾機(jī)的處理能力通常比板框式壓濾機(jī)更高,因?yàn)楦裟な綁簽V機(jī)可以更好地承受高壓力和高溫。

總之,隔膜式和板框式壓濾機(jī)在結(jié)構(gòu)、操作方式、適用范圍、操縱能力和處理能力等方面存在差異,需要根據(jù)具體的生產(chǎn)需求和工藝要求進(jìn)行選擇。

]]>Plate and frame filter presses的操作說(shuō)明書一般包括以下內(nèi)容:

- 設(shè)備介紹:介紹板框式filter press的結(jié)構(gòu)和功能,以及各個(gè)配件的作用和使用方法。

- 操作步驟:詳細(xì)介紹板框式壓濾機(jī)的操作步驟,包括濾板的排列、濾布的更換、污泥的注入、過(guò)濾壓力和時(shí)間的設(shè)置等。

- 維護(hù)保養(yǎng):介紹板框式壓濾機(jī)的維護(hù)保養(yǎng)方法,包括濾板的清洗、濾布的更換、油泵的保養(yǎng)、密封圈的更換等。

- 設(shè)備參數(shù):介紹板框式壓濾機(jī)的參數(shù),如工作壓力、過(guò)濾面積、過(guò)濾壓力、過(guò)濾溫度等。

- 參考文件:列出操作說(shuō)明書的相關(guān)參考文件,如設(shè)備安裝說(shuō)明、設(shè)備維護(hù)說(shuō)明、設(shè)備操作手冊(cè)等。

以上是板框式壓濾機(jī)的操作說(shuō)明書的一般內(nèi)容,具體內(nèi)容可能因不同型號(hào)和制造商而有所不同。在使用設(shè)備之前,建議先仔細(xì)閱讀說(shuō)明書,并按照說(shuō)明書的指導(dǎo)進(jìn)行操作和維護(hù)保養(yǎng)。

煤泥是選煤廠對(duì)原煤進(jìn)行洗選加工過(guò)程的副產(chǎn)品。對(duì)于動(dòng)力煤選煤廠煤泥一般是指原生煤泥,煉焦煤選煤廠煤泥一般是指浮選尾煤煤泥。一部分煤泥粒度組成較粗的選煤廠可采用加壓過(guò)濾機(jī)回收,少數(shù)選煤廠煤泥采用帶式壓濾機(jī)回收,絕大多數(shù)選煤廠的煤泥回收和關(guān)鍵把關(guān)設(shè)備都是采用板框式壓濾機(jī)。我國(guó)選煤廠采用板框壓濾機(jī)回收的煤泥濾餅水分通常在 25% ~ 40%之間,絕大多數(shù)煤泥發(fā)熱量在 10. 49 ~ 14. 64 MJ / kg 之間。這些煤泥由于水分高、發(fā)熱量低,外形呈現(xiàn)粘濕的 “團(tuán)塊狀”,直接摻入產(chǎn)品煤絕大多數(shù)用戶不接受,只能落地堆存。位于缺煤地區(qū)的選煤廠落地煤泥尚可低價(jià)就地銷售,位于煤炭集中產(chǎn)區(qū)的選煤廠煤泥很大一部分被廢棄。既浪費(fèi)了資源、又由于煤泥的運(yùn)輸和自燃造成嚴(yán)重的環(huán)境污染,煤泥的出路問(wèn)題甚至成為制約選煤廠生產(chǎn)的重要因素。近年來(lái),許多選煤廠為解決煤泥落地問(wèn)題,采用了新型隔膜式壓濾機(jī)、穿流式壓濾機(jī)等,試圖通過(guò)二次壓榨、空氣穿流等技術(shù)來(lái)降低煤泥水分。從總體上看,除個(gè)別選煤廠取得較理想效果外,大部分選煤廠煤泥的水分降低幅度有限。部分選煤廠采用煤泥火力干燥工藝對(duì)煤泥進(jìn)行降水,取得了比較好的效果和經(jīng)濟(jì)效益,煤泥干燥幾乎成為解決煤泥落地問(wèn)題的終極手段。目前,最常用的煤泥干燥設(shè)備有滾筒式干燥機(jī)和旋翼式干燥機(jī),一般可降低煤泥的水分 10% ~ 15%,提高煤泥發(fā)熱量 2. 09 ~ 3. 35 MJ / kg,烘干后的煤泥產(chǎn)品呈現(xiàn)非常松散的 “顆粒狀”,可以摻入產(chǎn)品煤或者就地銷售,提高了煤泥的附加值。煤泥干燥工藝的推廣應(yīng)用很大程度上解決了煤泥的出路問(wèn)題,但隨著國(guó)家環(huán)保政策的日益趨嚴(yán),采用燃煤產(chǎn)生熱煙氣干燥煤泥的技術(shù)路線通過(guò)環(huán)保驗(yàn)收的難度已經(jīng)非常大,很多地區(qū)已經(jīng)禁止新建燃煤火力干燥項(xiàng)目,部分在生產(chǎn)的煤泥干燥車間也被要求補(bǔ)建脫硫、脫硝設(shè)施,甚至被要求關(guān)停。在以上背景下,部分選煤廠從煤泥減量化入手,大量采用弛張篩、交叉篩等,通過(guò)原煤預(yù)先脫粉來(lái)實(shí)現(xiàn)煤泥的減量化。這些措施整體上有一些效果,但都沒(méi)有從根本上解決煤泥的出路問(wèn)題。為了解決煤泥回收產(chǎn)品水分高、粘性大難題,近期國(guó)內(nèi)有設(shè)備廠商另辟蹊徑,借鑒污泥回收行業(yè)部分技術(shù)經(jīng)驗(yàn),開發(fā)出專門適用于選煤廠煤泥回收的超高壓板框壓濾機(jī)。該型壓濾機(jī)采用遠(yuǎn)超常規(guī)板框式、隔膜式壓濾機(jī)的入料壓力、壓榨壓力,大幅度降低了煤泥產(chǎn)品的水分,配合煤泥破碎機(jī)將煤泥產(chǎn)品破碎成 “干粉狀”,完全具備摻入產(chǎn)品煤銷售的條件。該項(xiàng)技術(shù)在華東、陜北、彬長(zhǎng)等地區(qū)的應(yīng)用效果表明,超高壓壓濾機(jī)的煤泥水分可以比普通板框式、隔膜式壓濾機(jī)的煤泥水分平均降低 5%~ 10%左右,發(fā)熱量提高 1. 26 ~ 2. 09 MJ / kg,為選煤廠實(shí)現(xiàn) “無(wú)泥化”生產(chǎn),在解決選煤廠煤泥出路問(wèn)題的同時(shí),也都取得了可觀的經(jīng)濟(jì)效益。

2 超高壓壓濾機(jī)技術(shù)特征高壓diaphragm filter press機(jī)架由止推座、油缸座、兩側(cè)梁板和油缸組件組成,所有濾板均裝配在側(cè)梁板上,并可沿側(cè)梁板上導(dǎo)軌作水平方向移動(dòng),兩側(cè)梁板上配裝濾板移動(dòng)裝置,能自動(dòng)完成拉板和脫料工作,濾板 4 塊 1 組,實(shí)現(xiàn)快速脫料。油缸在液壓系統(tǒng)驅(qū)動(dòng)下推動(dòng)壓緊板將所有濾板壓緊在機(jī)架中,達(dá)到液壓系統(tǒng)工作壓力后進(jìn)入自動(dòng)保壓狀態(tài),隨后開始進(jìn)料過(guò)濾,進(jìn)料結(jié)束后,向水模濾板通入高壓壓榨水壓榨濾餅,降低煤泥濾餅含水率。以濾板規(guī)格為 2000mm×2000mm 的超高壓壓濾機(jī)為例,說(shuō)明超高壓壓濾機(jī)與板框式、隔膜式等普通壓濾機(jī)在機(jī)體結(jié)構(gòu)和工藝系統(tǒng)方面的主要區(qū)別如下:

( 1) 普通隔膜式板框壓濾機(jī)的濾板材質(zhì)一般為高分子聚合材料,濾腔厚度一般為 30 ~ 35 mm。超高壓壓濾機(jī)的濾板為可承受超高工作壓力的鑄鋼材質(zhì),濾腔厚度達(dá)到 60 mm,濾餅體積比傳統(tǒng)壓濾機(jī)幾乎增加了 1 倍。全鋼濾板不但耐壓強(qiáng)度高,而且工作壽命長(zhǎng),使用壽命可達(dá) 3 a 以上;

( 2) 普通壓濾機(jī)的頂緊、回程液壓油缸為共用,一般采用單缸或雙缸。超高壓壓濾機(jī)則為 16液壓油缸,其中,頂緊 12 缸,回程 4 缸。頂緊油缸為慢速缸、回程油缸為快速缸。

( 3) 超高壓壓濾機(jī)的工作面積可達(dá) 800 m2,而所謂的高分子材質(zhì)超高壓壓濾機(jī)的工作面積一般只能達(dá)到 300 ~ 400 m2,工作面積不到本機(jī)的一半。因此,單臺(tái)超高壓鋼制壓濾機(jī)的處理能力更大;

( 4) 普通隔膜式壓濾機(jī)的隔膜與高分子濾板結(jié)構(gòu)上復(fù)合為一個(gè)整體,超高壓壓濾機(jī)的隔膜則為聚氨酯薄膜式單獨(dú)設(shè)置;

( 5) 普通壓濾機(jī)的入料壓力一般為 0. 6 ~0. 8 MPa,超高壓壓濾機(jī)的入料壓力一般為 1. 2 ~1. 5 MPa,基本為普通壓濾機(jī)的 1. 5 ~ 2. 0 倍。

( 6) 普通隔膜壓濾機(jī)一般采用高壓風(fēng)作為壓榨介質(zhì),少量用水作為壓榨介質(zhì)。風(fēng)力壓榨工作壓力 一 般 為 0. 8 ~ 1. 0 MPa,水力壓榨可達(dá)到2. 0 ~ 3. 0 MPa。而鋼制超高壓壓濾機(jī)則采用水作為壓 榨 介 質(zhì), 壓榨工作壓力一般為 5. 0 ~10. 0 MPa,是普通壓濾機(jī)正常工作壓力的 5 ~ 10倍,這是超高壓壓濾機(jī)與普通壓濾機(jī)的最大區(qū)別,也是煤泥濾餅水分能夠大幅度降低,實(shí)現(xiàn)“泥變煤”的關(guān)鍵性技術(shù)因素。目前,市場(chǎng)也出現(xiàn)高分子材質(zhì)濾板的超高壓壓濾機(jī),但是,一般二次壓榨的工作壓力只有 3. 0 ~ 4. 0 MPa,最高不超過(guò) 5. 0 MPa,而鋼制超高壓壓濾機(jī)的二次壓榨壓力設(shè)計(jì)可最高可達(dá) 10. 0 MPa。目前,實(shí)際生產(chǎn)中驗(yàn)證的最高壓榨壓力已經(jīng)接近 8. 0 MPa。

( 7) 普通壓濾機(jī)入料一般采用機(jī)體尾部集中進(jìn)料或者頭、尾部分別進(jìn)料,超高壓壓濾機(jī)則采用濾板側(cè)部分散進(jìn)料,每塊濾板都有進(jìn)料管。因此,進(jìn)料速度更快,進(jìn)料時(shí)間更短。普通壓濾機(jī)通常為明流、暗流二種排液方式,超高壓壓濾機(jī)則為明流、滴水排液 2 種方式相結(jié)合,濾液排出速度也更快。超高壓壓濾機(jī)與普通隔膜式壓濾機(jī)的工作循環(huán)時(shí)間接近,一般為 40 ~ 50 min,但處理能力可達(dá) 1. 5 ~ 2. 0 倍,濾餅水分可降低 5% ~ 15%,發(fā)熱量提高 1. 26 ~ 3. 35 MJ / kg;( 8) 普通隔膜式壓濾機(jī)的濾餅一般呈 “團(tuán)塊狀”,通過(guò)鉸刀式煤泥破碎機(jī)破碎后的效果欠佳,一般情況下無(wú)法直接摻入產(chǎn)品煤,只能落地銷售或排棄。而超高壓壓濾機(jī)壓榨后的煤泥濾餅水分低、發(fā)熱量高,完全呈現(xiàn)比較堅(jiān)硬的 “固體”狀態(tài),經(jīng)過(guò)破碎后的最終煤泥產(chǎn)品完全呈現(xiàn)十分松散的 “粉粒狀”,可十分方便地?fù)饺氘a(chǎn)品煤銷售或單獨(dú)銷售。

3 超高壓壓濾系統(tǒng)配套設(shè)備

( 1) 入料泵: 超高壓壓濾機(jī)入料配套可采用單級(jí)或雙級(jí)離心泵,也可以采用壓力較高的隔膜泵。其中,雙級(jí)離心泵適用濃度高、流量大、高揚(yáng)程的工況,入料壓力可達(dá)到 1. 2 MPa 以上。

( 2) 壓榨泵: 超高壓壓濾機(jī)壓榨可選用高壓力、小流量的多級(jí)離心泵或往復(fù)泵,該泵最高工作壓力應(yīng)該達(dá)到 10. 0 MPa 以上。

( 3) 破碎機(jī): 超高壓壓濾機(jī)的煤泥濾餅水分低,厚度大,煤質(zhì)特性已經(jīng)接近 “塊煤”,采用錘式破碎機(jī)可取得較滿意破碎效果。

( 4) 控制系統(tǒng): 每套超高壓隔膜壓濾系統(tǒng)自帶 1 套 PLC 控制系統(tǒng),該系統(tǒng)可以對(duì)壓濾機(jī)工作的頂緊、入料、保壓、壓榨、回水、松開、卸料等過(guò)程進(jìn)行全自動(dòng)化的程序控制,過(guò)程控制參數(shù)可根據(jù)實(shí)際的煤質(zhì)指標(biāo)進(jìn)行人工調(diào)整。控制系統(tǒng)還帶有壓濾機(jī)智能入料、智能排序卸料等功能,使得壓濾車間現(xiàn)場(chǎng)基本可實(shí)現(xiàn)無(wú)人值守。

4 超高壓壓濾機(jī)的應(yīng)用陜北朱家峁選煤廠原設(shè)計(jì)煤泥回收采用普通板框式壓濾機(jī)回收,煤泥水分在 28% ~ 33%之間,由于煤泥水分高、發(fā)熱量低,常年就地低價(jià)銷售,既影響選煤廠的經(jīng)濟(jì)效益,也污染了環(huán)境。為此,選煤廠決定采用超高壓壓濾機(jī)取代普通板框式壓濾機(jī)進(jìn)行煤泥脫水,取得了非常明顯的效果。普通板框壓濾機(jī)與超高壓壓濾機(jī)進(jìn)行煤泥回收前后的工作效果對(duì)比見表 1。

從表 1 可以看出,陜北朱家峁選煤廠的超高壓壓濾機(jī)與普通板框壓濾機(jī)回收煤泥相比,水分大約降低 8% ~10. 5%,發(fā)熱量提高 1. 49~1. 88 MJ/ kg。對(duì)其進(jìn)行簡(jiǎn)單的經(jīng)濟(jì)效益分析如下:選煤廠每年實(shí)際生產(chǎn)濕煤泥量約為 11 萬(wàn) t /a,設(shè)計(jì)采用 1 臺(tái) 800 m2 超高壓壓濾機(jī),最大處理煤泥能力可達(dá) 20 萬(wàn) t /a。超高壓壓濾機(jī)比普通廂式壓濾機(jī)的煤泥水分按平均降低 8%考慮,濕煤泥單價(jià)按當(dāng)?shù)貙?shí)際就地銷售單價(jià) 65 元/t 計(jì)算,壓濾機(jī)運(yùn)行成本按 12 元/t 考慮,壓榨后的干煤泥形態(tài)為 “粉狀”,全部摻入產(chǎn)品煤銷售,噸煤泥售價(jià)根據(jù)發(fā)熱量按當(dāng)?shù)孛禾渴袌?chǎng)價(jià)格進(jìn)行折算,約合 450 元/t。則該廠超高壓壓濾機(jī)煤泥回收項(xiàng)目的年經(jīng)濟(jì)效益簡(jiǎn)要計(jì)算如下:經(jīng)濟(jì)效益=干煤泥量×干煤泥價(jià)格-濕煤泥量×濕煤泥價(jià)格-濕煤泥量×噸煤加工成本。經(jīng)濟(jì)效益 = 11 × 90% × 450 - 11 × 65 - 11 × 12 =3608( 萬(wàn)元/a) 。從計(jì)算結(jié)果可以看出,采用超高壓壓濾機(jī)取代普通板框式壓濾機(jī)后,超高壓壓濾煤泥回收項(xiàng)目的經(jīng)濟(jì)效益非常好,全部投資不到 2 a 即可收回。即使煤泥量按 50%摻入最終產(chǎn)品煤進(jìn)行銷售或者煤炭市場(chǎng)價(jià)格出現(xiàn)較大幅度波動(dòng),該煤泥回收項(xiàng)目的經(jīng)濟(jì)效益仍然非常可觀。某超高壓壓濾機(jī)設(shè)備廠商還利用小型超高壓工業(yè)試驗(yàn)型壓濾機(jī)對(duì)陜北某大型礦區(qū)多座選煤廠的煤泥進(jìn)行了超高壓壓濾試驗(yàn)。試驗(yàn)結(jié)果表明,與普通廂式壓濾機(jī)相比,超高壓壓濾機(jī)的煤泥水分降低幅度可達(dá) 3% ~ 7. 5%,發(fā)熱量可提高約0. 63 ~ 1. 67 MJ / kg,其它選煤廠的煤泥產(chǎn)品水分降低幅度介于二者之間。但是,所有選煤廠壓濾后的煤泥產(chǎn)品經(jīng)過(guò)破碎處理都可以呈現(xiàn) “松散”狀態(tài),只要產(chǎn)品煤的質(zhì)量要求允許,都可以非常均勻地?fù)饺胱罱K產(chǎn)品煤。目前,超高壓壓濾機(jī)已經(jīng)在濟(jì)寧、榆林、彬長(zhǎng)等礦區(qū)的 5 座選煤廠投入使用,煤泥產(chǎn)品降水幅度都非常可觀。除一些技術(shù)細(xì)節(jié)還需完善優(yōu)化外,主機(jī)設(shè)備和工藝系統(tǒng)均經(jīng)過(guò) 2 a 左右時(shí)間的實(shí)際生產(chǎn)考驗(yàn),主要技術(shù)已經(jīng)基本成熟,可以大范圍推廣應(yīng)用。需要注意的是,為了提高煤泥摻配產(chǎn)品煤的數(shù)量,并進(jìn)行控制和調(diào)節(jié),選煤廠建設(shè)超高壓項(xiàng)目最好配套開發(fā)煤泥智能摻配系統(tǒng)。包括: 煤泥的儲(chǔ)存緩沖、智能返煤、在線計(jì)量、在線檢測(cè)、在線給料、智能定量摻配控制軟件等。煤泥自動(dòng)摻配系統(tǒng)應(yīng)該實(shí)現(xiàn)煤泥摻配數(shù)量的在線無(wú)級(jí)可調(diào),使摻配效果均勻,以確保最終產(chǎn)品煤的質(zhì)量穩(wěn)定。

5 結(jié) 語(yǔ)超高壓隔膜壓濾機(jī)的機(jī)體結(jié)構(gòu)、工藝運(yùn)行條件等與傳統(tǒng)的板框式壓濾機(jī)有著很大不同,除了濾板腔室厚度增加近 1 倍外,還大幅度提高了壓濾機(jī)的壓榨工作壓力,達(dá)到 5. 0 ~ 10. 0 MPa,成為實(shí)現(xiàn) “泥變煤”過(guò)程的關(guān)鍵技術(shù)因素,這在某種程度上可視為是煤泥回收的 “顛覆性”技術(shù),未來(lái)應(yīng)該具有廣泛的市場(chǎng)應(yīng)用前景。超高壓壓濾機(jī)與傳統(tǒng)廂式壓濾機(jī)相比,根據(jù)煤泥粒度組成和水分特性的不同,煤泥濾餅水分一般可降低 5% ~ 10%,發(fā)熱量可提高 1. 05 ~ 2. 51MJ / kg,最終煤泥產(chǎn)品呈 現(xiàn) 完 全 的 “松 散” 狀態(tài)。采用超高壓壓濾機(jī)后,煉焦煤選煤廠的煤泥可全部摻入中煤銷售,動(dòng)力煤選煤廠的煤泥可部分或全部摻入最終產(chǎn)品煤或單獨(dú)銷售,大大提高了副產(chǎn)品煤泥的經(jīng)濟(jì)附加值,可大幅度增加選煤廠的經(jīng)濟(jì)效益。同時(shí),避免了煤炭資源浪費(fèi)和煤泥運(yùn)輸、儲(chǔ)存過(guò)程對(duì)環(huán)境造成的污染。已經(jīng)建成的幾座選煤廠超高壓壓濾項(xiàng)目均實(shí)現(xiàn)了 “無(wú)泥化”生產(chǎn)。尤其針對(duì)水分高、灰分低、發(fā)熱量提升潛力大的煤泥,采用超高壓壓濾機(jī)替代傳統(tǒng)的板框式壓濾機(jī)效果更有巨大優(yōu)勢(shì)。超高壓壓濾機(jī)回收煤泥技術(shù)為解決我國(guó)選煤廠低灰分煤泥落地?fù)p失資源和環(huán)保達(dá)標(biāo)問(wèn)題提供了最有前途、最為可行的回收技術(shù)途徑。從目前的實(shí)際使用結(jié)果看,其煤泥產(chǎn)品降低水分的幅度略小于煤泥火力干燥,但是不用燃燒煤炭產(chǎn)生熱煙氣,不存在環(huán)保問(wèn)題,運(yùn)行成本也低于煤泥火力干燥。對(duì)于采用傳統(tǒng)板框式壓濾機(jī)工作效果不佳或者煤泥火力干燥使用受到限制的選煤廠,超高壓壓濾機(jī)是一種可行的替代方案,應(yīng)給與高度重視。由陜西正通煤業(yè)有限公司與濱海金地礦業(yè)工程技術(shù)( 北京) 有限公司聯(lián)合開發(fā)的 《煤泥超高壓壓濾脫水回收關(guān)鍵工藝技術(shù)的研究與應(yīng)用》項(xiàng)目已經(jīng)通過(guò)了煤炭工業(yè)協(xié)會(huì)組織的專家鑒定。專家對(duì)超高壓壓濾技術(shù)的意見認(rèn)為:

( 1) 開發(fā)了全鋼材質(zhì)濾板、高分子材質(zhì)隔膜、復(fù)合濾布等耐超高壓力的壓濾機(jī)部件,并驗(yàn)證了部件在超高壓壓力狀態(tài)下工作的可靠性。基于入排料時(shí)間排序等精準(zhǔn)控制,實(shí)現(xiàn)了超高壓壓濾機(jī)智能化運(yùn)行。

( 2) 優(yōu)化了板框壓濾機(jī)的入料壓力、壓榨壓力,實(shí)現(xiàn)了板框壓濾機(jī)在 5 ~ 8. 0 MPa 超高壓壓力環(huán)境下的穩(wěn)定工作。較普通板框壓濾機(jī)工作壓力提高 了 6 ~ 10 倍,煤泥產(chǎn)品水分降低 5% ~10%,發(fā)熱量提高 1. 26 ~ 5. 51 MJ / kg,實(shí)現(xiàn)了煤泥提質(zhì)。

( 3) 基于超高壓壓濾機(jī)的煤泥濾餅特點(diǎn),開發(fā)了新型煤泥破碎工藝,實(shí)現(xiàn)了煤泥產(chǎn)品由 “高水分、高粘濕、團(tuán)快狀”向 “低水分、高松散、粉末狀”的轉(zhuǎn)變,為煤泥最終摻入產(chǎn)品煤銷售創(chuàng)造了有利條件。

( 4) 研制了智能化摻配系統(tǒng),包括在線/離線檢測(cè)、自動(dòng)給料、軟件控制等模塊,提高了產(chǎn)品煤質(zhì)量的穩(wěn)定性和市場(chǎng)適應(yīng)性。目前,超高壓壓濾機(jī)技術(shù)已經(jīng)在陜北的朱家峁,彬長(zhǎng)礦區(qū)的高家堡、亭南,濟(jì)寧礦區(qū)的唐口等選煤廠得到了應(yīng)用,并且經(jīng)過(guò)了 2 a 左右的生產(chǎn)實(shí)踐驗(yàn)證,各項(xiàng)技術(shù)經(jīng)濟(jì)指標(biāo)非常理想。國(guó)內(nèi)有設(shè)備廠商也開發(fā)出了有機(jī)高分子材質(zhì)濾板的超高壓壓濾機(jī),并實(shí)現(xiàn)了在個(gè)別礦區(qū)的工業(yè)應(yīng)用,但是,鋼制濾板的超高壓壓濾機(jī)工作壓力更高、工作面積更大,適應(yīng)范圍更廣,技術(shù)上更有優(yōu)勢(shì)。超高壓壓濾機(jī)目前存在的最大問(wèn)題是設(shè)備單機(jī)價(jià)格較高,投資大。隨著超高壓壓濾機(jī)的大范圍推廣,該機(jī)價(jià)格高的問(wèn)題會(huì)逐步得到解決。

超高壓壓濾機(jī)??? ?Enquiry: 188517-18517

]]>1 Problems of moisture control in refined coal products

The refined coal of the plant consists of four sub-products, namely, heavy medium refined coal, final refined coal, primary flotation refined coal and secondary flotation refined coal, with the ratio of 0.55∶0.25∶0.12∶0.08. The four sub-products are produced by different equipments, and then uniformly enter into the refined coal belt, which is transferred to the refined coal silo to become the final refined coal product. The moisture fluctuation of any one of the sub-products will affect the moisture of the final refined coal product. In the case of fixed production process and equipment, the moisture of each sub-product depends on the process performance of the equipment. However, when the moisture fluctuates slightly within a production shift during the production process, the equipment is generally not overhauled, adjusted or replaced for the sake of continuous production. In the production process, every hour to do the ash check, but the moisture is not a candidate for "shipping moisture" as a guide, back to check the coal quality and equipment, moisture control lags behind. There are a lot of debris in the raw coal, cotton yarn, small pieces of wood and other items clogging the fine coal desorption sieve, centrifuge screen basket, affecting the effect of product dewatering; fine coal slime content in the raw coal is large, the coarse and fine coal centrifuge screen basket sticky slime, the effect of dewatering is poor. There is the phenomenon that the equipment is running and leaking, and there is the phenomenon that foreign water enters into the fine coal products, and at the same time, there is the phenomenon that the workers' sense of responsibility is not strong, and the belt machine and scraper machine bring the water directly into the fine coal products.

2 Main dewatering equipment and parameters for refined coal products

The fine coal product handling equipment in the Coal Processing Plant Headquarters includes a coarse fine coal centrifuge dewaterer, fine coal mud centrifuge dewaterer, and fine coal mud settling centrifuge dewaterer,Fine Coal Filter Press There are 4 kinds of dewatering equipment, the dewatering requirements, process parameters are different, specific equipment models and technical parameters.

3 Specific measures to reduce the moisture of refined coal products

3.1 Enhanced cleaning of equipment

The coal preparation workshop refines the internal market implementation programme, formulates detailed equipment cleaning standards, rewards and penalties to the team, to the individual, and clarifies the acceptance signature process to ensure the effect of equipment cleaning. Enhance the cleaning of de-balling screen grading section during the stopping period to reduce the clogging of screen plate and ensure the normal grading of heavy fine; check the centrifuge screen basket and feel the centrifuge centrifugal liquid to ensure that the screen basket is intact; flush and clean the fine coal settling centrifuge screen basket and filter press cloth to ensure that the centrifuge screen basket, filter press cloth and filtrate nozzle are intact. During the production process, clean the debris on the screen grate every 1 h to ensure that the screen surface is free of debris and the screen holes are not blocked. Every 2 h on the coarse and fine coal centrifuge, arc sieve striker operation (striking interval time adjustment) and arc sieve dewatering effect of the inspection, and make relevant records, and found that the problem is timely reported to deal with. Observe the working condition of the arc sieve in the middle of the shift, and when there are phenomena such as water running away and material piling up on the surface of the sieve, according to the actual situation, take measures such as turning around, cleaning the surface of the sieve and replacing the surface of the sieve, so as to ensure the working effect of the arc sieve.

3.2 Enhanced maintenance of equipment

The installation and maintenance centre pays attention to the working condition of each dewatering equipment every day, analyses and finds out the reasons from the aspect of equipment when abnormal moisture occurs, and improves the performance of equipment by adjusting, replacing the accessories or transforming the equipment, so as to reach or exceed the dewatering performance of the equipment at the time of leaving the factory, and ensure that the moisture of the product meets the standard.The LLL-type centrifuges are measured once a shift, and the screen slits of the screen basket of the roughness and fineness centrifuges are maintained in the range of 0.35 to 0.4 mm. Replace the sieve basket when the sieve gap exceeds 0.4 mm after wear and tear. The screen basket gap is maintained at 1-3 mm, and once the gap changes, it will be adjusted in time by various methods to ensure the equipment process.

The parameters meet the requirements for coal selection.

The feeding pressure of the sedimentation centrifuge is around 0.3 MPa, if the pressure fluctuates, the feeding equipment will be overhauled immediately, the overflow parts will be replaced, and when the opening rate of the sieve slit decreases, it will be cleaned in coordination with the coal selecting workshop, so as to ensure the performance of the equipment. Filter press head feed pressure is between 0.7 and 0.8 MPa, feed pressure is between 0.5 MPa, and press pressure is around 0.6 MPa. The installation and maintenance centre always pays attention to the moisture of refined coal and the operation of the equipment, and if the pressure fails to meet the requirements, it will find out the reasons for the equipment at the first time, and if it is necessary to change the pump, it will be changed under the arrangement of production scheduling, so as to reduce the moisture of refined coal. Make two-dimensional code for each dewatering equipment and install it in the appropriate position of the equipment. When the chartered personnel of the installation and maintenance centre inspect the equipment, they can scan the code to fill in the basic information of the equipment and the inspection and maintenance records, which will form the equipment history file and the maintenance record file. According to the equipment files, a dynamic maintenance schedule can be formed to remind the team of the maintenance deadline in real time, helping the team to arrange preventive maintenance measures in advance, and improving the planning and reliability of equipment maintenance.

3.3 Strengthening production process control

There are many factors affecting the product moisture, Huaibei Coal Preparation Plant adopts QC total quality management, systematically analyses the factors affecting the moisture of each sub-product of refined coal, takes targeted measures, strengthens the control of the production process, and reduces the influence of the influencing factors on the sub-products of refined coal. Coal processing workshop coal every 10 min record of raw coal into the wash, to ensure that the supply of raw coal as far as possible uniform and stable, the processing speed control in the range of 310 ~ 330 t / h; reasonable adjustment of the vibrating screen de-mediation of circulating water dosage, to maintain a stable level of coarse coal slurry barrels, fine coal slurry drums, to ensure that the head of the arc screen material supply is stable; to maintain flotation into the quality of the concentration of material in the 80 ~ 90 g / L, to ensure that the quality concentration of flotation material stable [2]. Maintain the quality concentration of flotation feed at 80~90 g/L, ensure the flotation feed quality concentration is stable [2]; keep the liquid level of the material in the second flotation drum not less than 200 cm, ensure the feed of the second flotation filter press is sufficient; strictly control the use of anti-foaming water in the concentrate tank of the flotation machine, reduce the viscosity of the flotation foam, and improve the processing effect of the fine coal filter press. Strengthen the raw coal removal in the coal processing workshop to reduce the debris in the system and prevent the debris from clogging the sieve plate and screen mesh; increase the heavy-medium diversion to reduce the amount of coal sludge in the system and reduce the output of flotation coal; check whether the belt machine and scraper are stocked with water before starting the operation; and strictly manage the operation of centrifugal machines and filter presses to prevent the centrifugal liquid, filter press filtrate and other external water from entering the refined coal products. The quality inspection workshop carries out the moisture inspection of the primary flotation and secondary flotation of heavy-medium lump fine coal and coarse fine coal within 1 hour after adding coal in each shift. During the production process, when the moisture of heavy-medium lump coal is more than 5% and the moisture of rough coal is more than 13%, the chemist will report to the dispatching in time, and the dispatching will notify the coal selecting workshop and the safety and maintenance centre to investigate and deal with the problems on the spot, and reduce the moisture as soon as possible; when the moisture of heavy-medium lump coal is more than 6% and the moisture of rough coal is more than 15%, the dispatching will arrange to stop the car to deal with the problem, and only when the problem is solved can it start to add coal to production. Only after the problem is solved can the company start to add coal for production. During the production process, the final product moisture is weighted according to the output and moisture of each sub-product to guide the production control, changing the previous practice of passively controlling the moisture of fine coal products by "shipping water". The company has established a big data analysis library of coal production, including the production date of heavy media parameters, washing programme, raw coal information, production process and abnormalities, and analysed and recorded the production situation of the current shift after each shift, so as to provide references for the future production. At the same time, we firmly implement the "large diversion and water replenishment operation method, and systematically carry out mud removal to reduce the impact of high ash and fine mud on the dewatering process of fine coal products [3].

3.4 Enhancing technological transformation

After thorough investigation and demonstration, the coal preparation plant has implemented targeted technical modifications to further improve the reliability of the equipment and strengthen the foundation of reducing the moisture content of the refined coal products. Replace the coarse and fine coal arc sieve with a high aperture rate sieve plate with a slit of 0.4 mm and a back width of 0.8 mm, increase the coarse cut-off volume of the arc sieve, reduce the flotation feed volume of 20%, and improve the proportion of fine coal sub-products. Increase the arc screen exciter and striker to improve the working effect of the arc screen and reduce the moisture of the centrifuge feed. Compare withFilter Press ManufacturersIn cooperation with the company, we installed edge-feeding type filter press for secondary flotation concentrate dewatering, after the transformation, the press pressure of the filter press was increased from 13 MPa to 20 MPa, and the filtration area was increased from 490 m2 to 550 m2, so as to solve the problem of high moisture of the cake of KZG-type concentrate filter press while increasing the processing capacity. Open holes in the outer wall of the centrifuge, and draw high-pressure wind from the high-pressure air package all the way to the inside of the centrifuge, forming five air outlets facing the screen; install an electromagnetic blowing valve on the air package pipeline, and realise the function of blowing automatically for 30 s immediately after stopping the car through a relay and a time-delay controller, so as to blow off the debris adhering to the screen, and improve the working performance of the centrifuge. The research and development of the "unattended" system in the coal receiving pit realises that the coal feeder automatically allocates and adds coal according to the storage condition in the coal receiving pit, so as to supply coal of uniform quality and quantity to the maximum extent possible, and to reduce the influence of the change of coal quality and quantity on the production system.

3.5 Enhanced experimental analyses

Product quality inspection is the "eyes" of coal preparation plant, and experimental analysis is necessary to promote the "health" of coal preparation production system, which can provide the basis for guiding the production and optimising the production plan. Coal processing workshop, together with quality inspection workshop, carries out experimental comparative analysis of process adjustment, such as whether the materials in three or four rooms of primary flotation enter the secondary flotation machine, whether the materials in one or two rooms of primary flotation are doped with coarse or not, whether the heavy media slurry bucket is replenished with water or not during the large diversion, etc, in order to search for the best control scheme of moisture of refined coal products. The quality inspection workshop carries out "key moisture point" test, strengthens the statistical analysis, weekly, monthly, every ten days statistics of heavy medium, coarse and fine, primary and secondary flotation moisture changes, and guides the operation of dewatering operation of the coal processing workshop with the phased rule. According to the raw coal quality and incoming material quality concentration, particle size, viscosity, optimise the operating parameters of sedimentation centrifuge and filter press to ensure that the product moisture meets the standard. Carry out "comparative" test for dewatering equipment. Follow up the single and double dewatering equipments, compare the moisture, and provide timely feedback. We benchmark the advanced value of similar equipments in the industry, carry out targeted benchmarking management and promotion work, continuously track the dewatering situation after adjusting and maintaining the dewatering equipments, and then optimise and adjust the equipments again, so as to make the equipments reach the best working efficiency. Carry out experiments on parameters such as press pressure and press time of the filter press, and finally conclude that under the conditions of feed pressure of 0.6 MPa, feed time of 420 s, press pressure of 1.0 MPa, press time of 300 s, and side blowing pressure of 0.7 MPa, extending the side blowing time to 900 s can achieve better moisture index of secondary flotation coal products. Carry out experiments on the effect of overflow weir height of sedimentation centrifuge on products, and finally conclude that with the increase of overflow weir height, the diameter of gas-liquid interface decreases, the length of settling zone increases, the separation strength decreases, the average particle size of solid products decreases, the moisture of products increases, and the solids content in filtrate decreases. Reasonable selection of the optimal overflow weir height can reduce the moisture of the primary flotation coal product to a certain extent.

3.6 Strengthening education and training

The coal industry has been transformed from the past kind of rough and labour-intensive to knowledge-based technology, and in order to survive in the wave of reform, the enterprise must educate and train the workers, enhance their sense of belonging to the enterprise and sense of ownership, and consciously think about what the enterprise thinks and urgently need the enterprise's urgency. Carry out staff education and training, explain the importance of moisture index of fine coal, form a good atmosphere that everyone pays attention to the moisture index and participates in the control of the moisture index, and promote the maximisation of the enterprise's benefit. Systematically collate the factors affecting refined coal products, decompose them in a targeted way, and form operation points, so that the workers understand what to do, how to do it, and to what extent to do it; organise the relevant units to carry out the "Reducing the moisture of refined coal products" discussion activities by workshop, team and post, so as to collect ideas and promote the reduction of the moisture of refined coal products. According to on-site practice, carry out the abnormal treatment method of fine coal product moisture.

Summarise, combined with the post operation points, post common problems, post standardized operating procedures, etc. to do a good job in reducing the water content of fine coal products micro-course development, evaluation, hanging on the Internet, convenient for workers to consult and learn; organise knowledge and experience dissemination meetings, increase the strength of the post to pass on the efforts of the technical inheritance, and promote the skills of workers as a whole team to improve. Organize the revision of post operation process, promote work standardization, normalization, institutionalization, scientification; vigorously carry out technical competitions, "master and apprentice" activities, to create a "compare, learn, catch up, help and surpass" a good learning and competitive environment, to create a theoretical, technical and high-quality talent team. High-quality talent team.

3.7 Increased appraisal

Appraisal is the baton of behaviour, Huaibei Coal Preparation Plant clarifies the moisture control index of fine coal products and the moisture control index of fine coal sub-products, and increases the appraisal, so as to make the system become a strong backing to promote the reduction of the moisture of fine coal products. The leading group of the project to reduce the moisture of refined coal was set up to determine the moisture control target according to the current status of the process and the performance of the equipment: the moisture of the shipped refined coal is less than or equal to 9.5%, the moisture of the heavy-medium refined coal is less than or equal to 3.5%, the moisture of the coarse refined coal is less than or equal to 10.0%, the moisture of the primary flotation refined coal is less than or equal to 20.0%, and the moisture of the secondary flotation refined coal is less than or equal to 15.0%. Implementing the "double equal" assessment system, i.e., equal assessment of refined coal moisture and ash content, equal assessment of coal processing workshop, quality inspection workshop and installation and maintenance centre, to promote the coal processing workshop, quality inspection workshop and installation and maintenance centre to strengthen the communication and liaison, and to analyse and find out the reasons from the aspects of coal quality, equipment and operation, so as to make the moisture of refined coal products reach the assessment level and to ensure the quality of coal products meet the requirements. To make the moisture of fine coal products meet the assessment requirements. Scheduling coordinator does a good job in coordinating the work, and makes it clear that all relevant departments will sort out the details of materials needed to reduce the moisture content of refined coal products before the 20th of each month and report the material plan, and the material management department will contact the material branch of the group company to make purchases in a timely manner, track the arrival situation and issue the materials in a timely manner. The quality analysis meeting is held every month, in which the chief engineer of the plant, the relevant functional departments and the main leaders of the coal selecting workshop, quality inspection workshop, installation and maintenance centre and other workshops participate to analyse the coal quality situation, systematically find out the existing problems and improve them, and carry out rewards and punishments according to the completion situation, so as to promote the moisture control to meet the target requirements.

4 Conclusion

Product quality is the cornerstone of enterprise development. As an important indicator of product quality, especially for coking coal products, the moisture of fine coal will affect the coke yield and comprehensive energy consumption of downstream coking enterprises, increase the amount of ineffective transportation, increase the cost of transportation, and pollute the environment around the transportation line. This is contrary to the national carbon peak carbon neutral target and must be taken seriously. Through a series of measures, the headquarter of Huaibei Coal Preparation Plant has reduced the moisture of refined coal products from 10.2% to less than 9.5%, which is a very significant result and provides a useful reference for the control of moisture of refined coal products in the industry.

Sudong or Sodong (name)filter press 18851718517

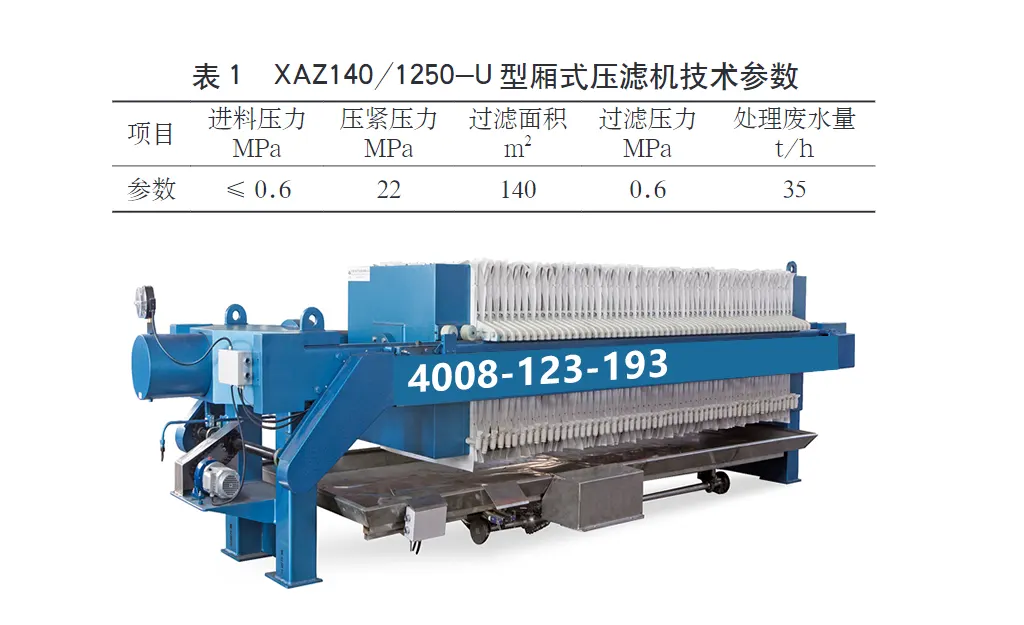

]]>a power plantHow to reduce the water content of chamber filter press cakePhase I of the 2×630 MW unit project adopts limestone-gypsum wet full flue gas desulphurisation (FGD) with one furnace and one tower desulphurisation device, and the design desulphurisation efficiency is not less than 95 %. The desulphurisation wastewater treatment system adopts XAZ140/1250-U chamber filter press, and the specific technical parameters are as shown in Table 1.

The filter plate of chamber filter press is quadrangular, the filter cloth is in the concave filter plate on the projecting part, from 2 quadrangular filter plate to form a closed filter chamber. The main advantages of chamber filter press are low loss of feed, fast filtration speed, high temperature and pressure resistance, good sealing performance, uniform cake, low water content, basically applicable to all solid-liquid separation industries.

2 Working Principle of Chamber Filter Press When the chamber filter press is working, the hydraulic cylinder will press all the filter plates between the movable head plate and the fixed tail plate, so that the adjacent filter plates form a sealed filter chamber, and the slurry will be fed from the feeding holes of the fixed tail plate with a certain pressure. After all the chambers are filled with slurry, the filtration process begins, and the slurry is separated from the solids and liquids by the pressure of the feed pump. Solid particles remain in the filter chamber due to the blockage of the filter cloth, and the filtrate is discharged through the filter cloth along the drain on the filter plate. After a period of time, the filtrate no longer outflow, that is, the completion of the dewatering process. At this time, you can stop feeding, through the hydraulic manipulation system adjustment, the head plate back to the original position; by the filter plate moving device will be pulled open one after another; the filter cake rely on self-weight fall off, and is located in the lower part of the belt to transport away. In order to prevent the filter cloth eyelets from clogging, affecting the filtering effect, the filter cloth needs to be cleaned after unloading the cake. So far, the whole filtering process is completed.

3 Problems and Improvement of Vane Filter Presses

3.1 Problems in the actual application, affected by a variety of factors, the water content of the filter cake of the chamber filter press is relatively large, and the effect of filtration is not ideal. The large water content of the cake causes the cake to become sludge-like, attached to the filter cloth. Even if you use a shovel to poke, you can't drop the whole piece, and some of them even need to rinse the filter cloth before the next cycle, resulting in high labour intensity of the staff and long unloading time.

3.2 Problem analysis The lower the feed concentration, the higher the moisture of the filter cake. When the concentration of feed material is low, fine particles are very easy to enter the eyelets of the filter cloth, pass through, block or cover them, so that the eyelets of the filter cloth will be blocked soon. With the increase of feed concentration, there will be more particles close to or to the filter cloth eyelets, due to mutual interference, the vast majority of particles can not enter the eyelets and the formation of arches and bridges on the eyelets, which can make the filter holes in a longer period of time is not seriously blocked. With the filtration process, the average particle size of the filter cake formed on the surface of the filter cloth along the feeding direction from the outside to the inside gradually increases, and the cake resistance gradually decreases, so that the dewatering of the inner side of the cake (close to the side of the filter cloth) is affected, and this effect is gradually strengthened with the decrease in the concentration of the feeding material. After the study of the field conditions and a lot of tests, it was found that under the existing equipment, by adjusting the feed pressure, feed time, press [Abstract] A power plant chamber filter press in the application of the problem of large moisture content of the cake, the effect of filtration is not ideal. The problem was analysed, and it was confirmed that under the existing equipment and operating parameters, the filter press did not have the conditions to further reduce the water content of the cake. By increasing compressed air, the water content of the filter cake was reduced from 60 % to 10 %, which improved the sludge discharge efficiency. Parameters such as pressure and feed concentration can no longer effectively reduce the water content of the filter cake in the filter press, so it is necessary to propose an improvement programme.

3.3 Improvement programme In order to effectively reduce the water content of the filter cake in the chamber filter press, compressed air can be fed through the feed pipe after the feed of the filter press (unlike the diaphragm filter press). Compressed air automatic control device is added, and it can be switched directly through the DCS screen. The air and feed use the same inlet, when the feed is finished, close the feed valve and flush the feed pipe. After flushing, start conveying compressed air until no filtrate is discharged from the feed pipe to reach the state of equipment sludge discharge.

4 Conclusion

(1) Before using compressed air to reduce the water content of the filter cake, the filter cake in the filter press must be filled. If the cake is too thin, it will result in low water content of the cake at the inlet of compressed air, and the farther away it is, the higher the water content will be, and it will not even be able to play a role in reducing the water content.

(2) The time to pass into the compressed air needs to be determined according to the situation. Different materials, through the compressed air time is different. If the time is short, the water content of the cake is large; if the time is too long, it will cause the cake to dry out in contact with the filter cloth and attach to the filter cloth, increasing the workload.

(3) After adding compressed air, the material conveying pipeline needs to add a way of flushing water. Due to the influence of compressed air, the water content of the residual slurry in the feed pipe will also decrease, and further air-dry. After many times, the air-dried slurry will clog the pipe.

(4) After the transformation, after the actual operation verification, the effect of desliming has obvious improvement, the filter cake forming is more complete, the water content is as low as 10 %. the whole operation process can realise the continuous automatic cycle of mud, not only to improve the efficiency of the system mud, but also to reduce the frequency of manual on-site operation.